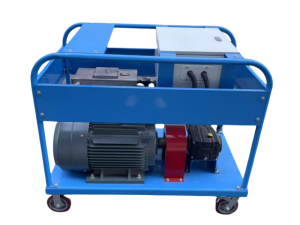

JMT-1-180BAR Motor Sewer Drain Cleaning Machine

| Модель | JMT-1 |

| Давление на выходе | 180bar/2600psi |

| Скорость потока воды | 55L/min |

| Диаметр плунжера | 28mm |

| Количество плунжеров | 3 |

| Входная скорость | 3600r/min |

| Pump Speed | 1450r/min |

| Ход плунжера | 21 мм |

| Motor Power | 15KW |

| Water Inlet Size | 1.5-inch |

Working Principles

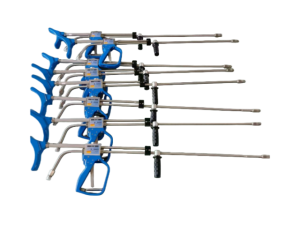

The high-pressure pump generates a high-pressure water jet. Connect the pipe unclogging nozzle to the pump via a high-pressure hose and place the nozzle directly inside the pipe to be unblocked.

As the high-pressure pump operates, the reaction force generated by the high-pressure water ejected from the rear of the nozzle rapidly pushes the nozzle forward. High-pressure water jets generated by the nozzle’s front and rear nozzle holes quickly clean the pipe.

As the pipe collector pulls the nozzle back, the high-pressure water flow flushes dirt out of the pipe bundle.

Applications: Used for unclogging and clearing clogged pipes in municipal, residential, and industrial parks.

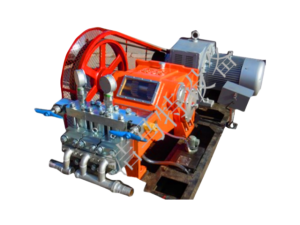

Особенности и преимущества продукта

1. Передовые технологии, компактная структура, плавная и надежная передача.

2. Стабильное и надежное давление, легкая регулировка.

3. Нержавеющая сталь, ударопрочное силиконовое масло и индикатор давления.

4. Forced lubrication on the power end reduces friction and improves lubricity, ensuring smooth and reliable transmission.

5. Кованая головка насоса из нержавеющей стали, прочная и долговечная.

6. Синхронная муфта обеспечивает стабильную работу.

7. Корпус насоса высокого давления изготовлен из ковкого чугуна; отличная теплоотдача, твердая текстура и устойчивость к деформации.

8. The equipment is equipped with a filter to precisely filter impurities in the incoming water, which is beneficial to extending the service life of the water pump

9. Available with either electric motor or diesel engine drive.

Applications Industry

1. Multi-application cleaning, including residential property pipe cleaning.

2. Multi-application cleaning, including municipal pipe cleaning and unclogging.

3. Multi-application cleaning, including diversion tunnel pipe cleaning.

4. Multi-application cleaning, including tunnel and culvert pipe cleaning.

5. Hull cleaning, deck cleaning, decontamination, and marine growth removal from ship bottoms.

6. Metallurgical equipment and metallurgical atomization.

7. Machinery manufacturing plants, including vessel/pipeline/rust/scale cleaning.

8. Cement plant pipe cleaning, removing grease and dirt from equipment surfaces.

9. Очистка, восстановление и т.д. гидравлической опоры горнодобывающей промышленности.

Подробная спецификация продукта

| Модели | Flow(m³/h) | Rated Flow Rate(l/min) | Номинальное давление (бар) | Power (kw) | Diesel Engine Power(kw) | Gasoline Engine Power(HP) |

| JMT-1 | 3.3 | 55 | 180 | 15KW | 28HP | 27HP |

| Jmt-2 | 4.8 | 80 | 180 | 22 кВт | 33KW | 37HP |

| JMT-2 | 7.2 | 135 | 180 | 37kw | 62kw | |

| JMT-2 | 10.2 | 170 | 280 | 90kw | 145w | |

| JMT-2 | 12.9 | 215 | 220 | 90kw | 145kw | |

| JMT-2 | 15 | 250 | 200 | 90kw | 145kw | |

| JMT-7 | 21 | 350 | 300 | 200kw | 264kw | |

| JMT-7 | 28.8 | 480 | 200 | 200kw | 264kw |

Случаи применения

Cement pipe cleaning

Sewer pipe cleaning

Square trench cleaning