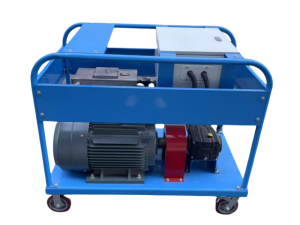

JMT-2 Series Water Jet Cutting and Blasting Equipment

| Модель | JMT-2 |

| Давление на выходе | 220bar/3190psi |

| Скорость потока воды | 250L/min |

| Диаметр плунжера | 50mm |

| Количество плунжеров | 5 |

| Входная скорость | 1480 об/мин |

| Pump Speed | 405r/min |

| Ход плунжера | 95mm |

| Мощность двигателя | 145kw/198HP |

| Метод смазки | Forced lubrication |

Особенности и преимущества продукта

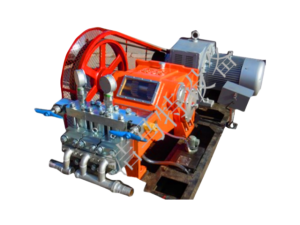

1. Передовые технологии, компактная структура, плавная и надежная передача.

2. Стабильное и надежное давление, легкая регулировка.

3. Нержавеющая сталь, ударопрочное силиконовое масло и индикатор давления.

4. Forced lubrication on the power end reduces friction and improves lubricity, ensuring smooth and reliable transmission.

5. Кованая головка насоса из нержавеющей стали, прочная и долговечная.

6. Синхронная муфта обеспечивает стабильную работу.

7. Корпус насоса высокого давления изготовлен из ковкого чугуна; отличная теплоотдача, твердая текстура и устойчивость к деформации.

8. The equipment is equipped with a filter to precisely filter impurities in the incoming water, which is beneficial to extending the service life of the water pump

9. Available with either electric motor or diesel engine drive.

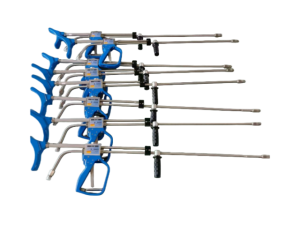

Water Jet Cutting and Blasting Equipment Actuator

Applications Industry

1. Multi-application industrial cleaning applications, including heat exchanger tube cleaning, condenser tube cleaning, air preheater cleaning, condenser cleaning, pipeline cleaning, reactor cleaning, filter cleaning, reboiler cleaning, tank cleaning, and equipment surface cleaning.

2. Pipeline pressure testing, valve/hose pressure testing, pressure vessel pressure testing, and water pressure testing.

3. Cement plant pipeline cleaning, equipment surface grease removal, scale removal, and rotary kiln tail cleaning.

4. Construction industry: car/truck cleaning, mixing drum/tank cleaning, tar/cement/adhesive cleaning.

5. Food processing plants: mixing tank cleaning, grease/sludge/residue removal, and evaporator/boiler cleaning.

6. Shipyards: rust and paint removal, hull cleaning, ship deck cleaning, fouling removal, and marine growth removal from ship bottoms.

7. Metallurgical equipment and metallurgical atomization.

8. Machinery manufacturing plants: rust/scale/scale removal from containers/pipes/tanks.

9. Mining hydraulic support cleaning and remanufacturing.

10. High-pressure water roughening of concrete.

Подробная спецификация продукта

| Модели | Rated Flow Rate(l/min) | Номинальное давление (бар) | Diesel Engine Power(kw) |

| JMT-6 | 170 | 1500 | 720kw |

| Jmt-6 | 200 | 1500 | 800kw |

Случаи применения

Pipe pile blasting drilling

Larsen H pile blasting drilling

4-hole cutter head blasting drilling

Single-head blasting drilling