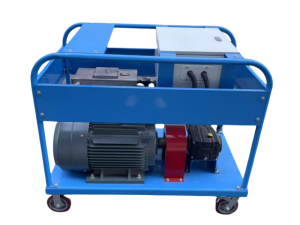

JMT-3 serie hogedrukreiniger

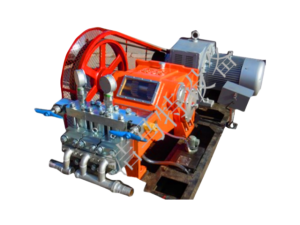

| Model | JMT-3 |

| Uitlaatdruk | 1000 bar/14500psi |

| Waterstroomsnelheid | 50 l/min |

| Diameter zuiger | 24 mm |

| Aantal plunjers | 3 |

| Invoersnelheid | 1480r/min |

| Pompsnelheid | 366 omw/min |

| Plunjerslag | 120 mm |

| Motorvermogen | 90 kW |

| Smeermethode | Geforceerde smering |

| Koelmethode | Waterkoeling |

Productkenmerken en -voordelen

1. Geavanceerde technologie, compacte structuur en soepele en betrouwbare transmissie.

2. Stabiele en betrouwbare druk, eenvoudig instelbaar.

3. Roestvrij staal, schokbestendige siliconenolie en drukweergave.

4. Geforceerde smering aan de aandrijfzijde vermindert de wrijving en verbetert de smering, wat zorgt voor een soepele en betrouwbare transmissie.

5. Gesmede roestvrijstalen pompkop, stevig en duurzaam.

6. Synchrone koppeling zorgt voor een stabiele werking.

7. Hogedruk pomphuis van nodulair gietijzer; uitstekende warmteafvoer, harde textuur en bestand tegen vervorming.

8. Drie filters filteren nauwkeurig de onzuiverheden in het binnenkomende water, waardoor de levensduur van de pomp wordt verlengd.

9. Het geforceerde waterkoelsysteem aan de hydraulische kant verlaagt de temperatuur van de plunjer.

10. Verkrijgbaar met aandrijving door elektromotor of dieselmotor.

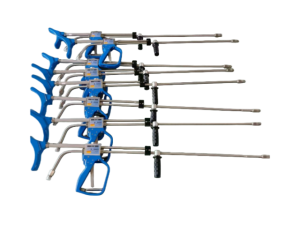

Toepassingen Industrie

1. Industriële reinigingstoepassingen voor meerdere toepassingen, waaronder het reinigen van warmtewisselaarbuizen, condensorbuizen, luchtvoorverwarmers, condensors, pijpleidingen, reactoren, filters, boilers, tanks en oppervlakken van apparatuur.

2. Druktests van pijpleidingen, druktests van afsluiters en slangen, druktests van drukvaten en water.

3. Reinigen van pijpleidingen van cementfabrieken, verwijderen van vet op apparatuuroppervlakken, verwijderen van kalkaanslag en reinigen van de rotatieoven.

4. Bouwindustrie: auto/vrachtwagen reinigen, mengtrommel/tank reinigen, teer/cement/lijm reinigen.

5. Voedselverwerkende fabrieken: mengtank reinigen, vet/slib/resten verwijderen, verdamper/ketel reinigen.

6. Scheepswerf: ontroesten, verf verwijderen, romp schoonmaken, scheepsdek schoonmaken, aangroei verwijderen en mariene aangroei verwijderen van scheepsbodems.

7. Metallurgische apparatuur en metallurgische verstuiving.

8. Installaties voor machinefabricage: reiniging van vaten, pijpen en tanks, verwijderen van roest en kalkaanslag.

9. Hydraulische ondersteuning voor mijnbouwreiniging, revisie en meer.

Gedetailleerde productspecificatie

| Invoersnelheid (omw/min) | 1480 | Plunjerslag (mm) | 100 | |||

| Verminderingsratio (i) | 4.45 | Pompsnelheid (omw/min) | 336 | |||

| Vermogen (kW) | 75 | 90 | 110 | Diameter plunjer (mm) | ||

| Nominale stroomsnelheid | Nominale afvoerdruk (bar) | |||||

| M³/H | L/min | |||||

| 2.4 | 40 | 1000 | 22 | |||

| 2.7 | 45 | 850 | 1000 | 24 | ||

| 3.12 | 52 | 750 | 900 | 1000 | 26 | |

| 3.6 | 60 | 650 | 800 | 950 | 28 | |

| 4.2 | 70 | 600 | 700 | 850 | 30 | |

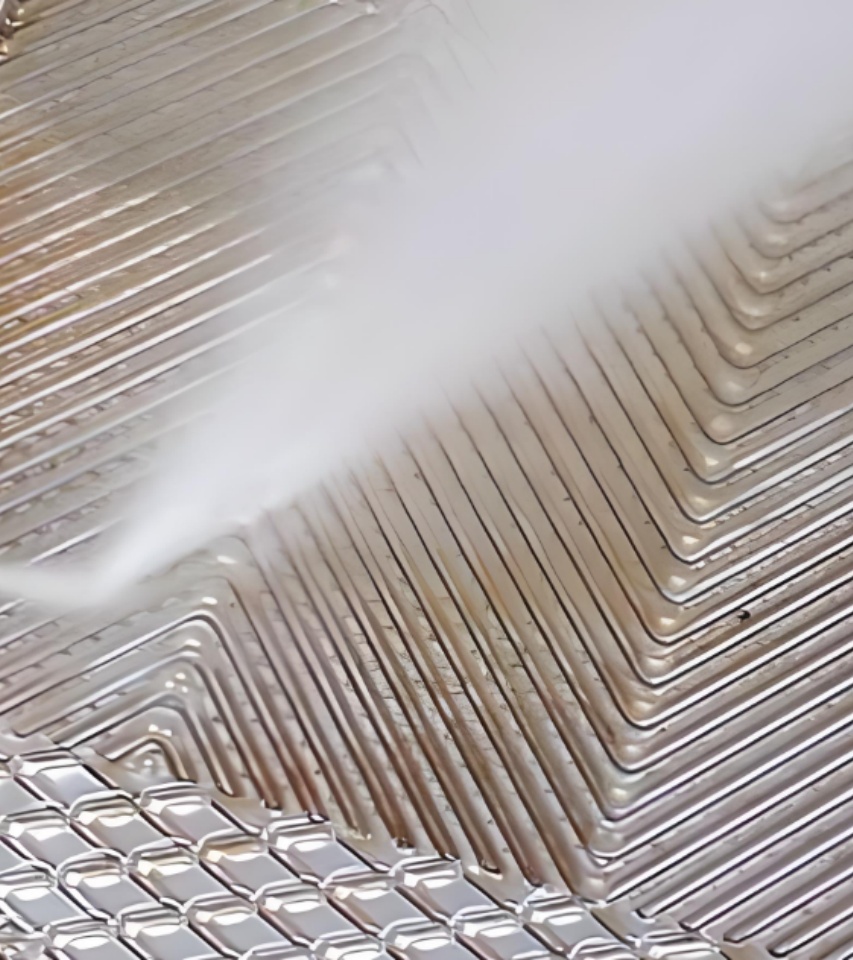

Toepassingsgevallen

Schoonmaken van platenwarmtewisselaar

Condensatiewarmtewisselaar reinigen

Verwijderen van scheepsverf