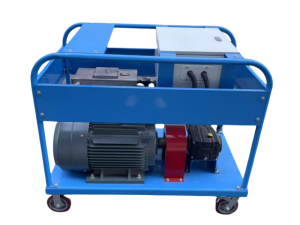

JMT series automatic cleaning system

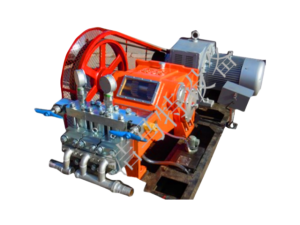

| Model | JMT-7 |

| Uitlaatdruk | 200 bar/7250 psi |

| Waterstroomsnelheid | 480L/min |

| Diameter zuiger | 70mm |

| Aantal plunjers | 3 |

| Invoersnelheid | 1480r/min |

| Pump Speed | 366r/min |

| Plunjerslag | 120mm |

| Motorvermogen | 200KW |

| Smeermethode | Forced Lubrication |

| Cooling Method | Water Cooling |

Productkenmerken en -voordelen

1. Geavanceerde technologie, compacte structuur en soepele en betrouwbare transmissie.

2. Stabiele en betrouwbare druk, eenvoudig instelbaar.

3. Roestvrij staal, schokbestendige siliconenolie en drukweergave.

4. Forced lubrication on the power end reduces friction and improves lubricity, ensuring smooth and reliable transmission.

5. Gesmede roestvrijstalen pompkop, stevig en duurzaam.

6. Synchrone koppeling zorgt voor een stabiele werking.

7. Hogedruk pomphuis van nodulair gietijzer; uitstekende warmteafvoer, harde textuur en bestand tegen vervorming.

8. The equipment is equipped with a filter to precisely filter impurities in the incoming water, which is beneficial to extending the service life of the water pump

9. Available with either electric motor or diesel engine drive.

Equipment Description

This equipment is a pass-through spray cleaning and drying line designed to meet the manufacturing industry’s growing demands for higher cleanliness standards and increased cleaning output. It integrates mature technologies such as spray cleaning, tunnel drying, and internal circulation drying. Its core features are as follows:

- Adopts stainless steel chain transmission, and is equipped with a low-pressure spray area, high-pressure washing area, air knife water-cutting area, tunnel-type internal circulation drying area, and loading/unloading area, with a high degree of automation.

- Aiming at the characteristics of workpieces with multiple types, complex shapes, and porous/deep-hole structures, a low-speed rotation function is set during the cleaning and drying process to ensure thorough cleaning and drying.

- Suitable for the production scenarios of metal utensils and hardware electrical appliances, it is an ideal automated cleaning equipment for relevant manufacturers.

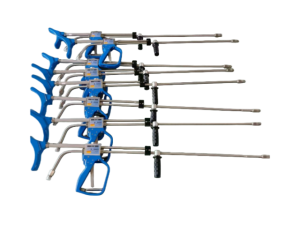

Purpose and Application Fields

- Purpose: Removes impurities such as cutting fluid, burrs, dirt, oil stains, and metal chips attached to the surface of parts.

- Application Fields: Automobile manufacturing, aluminum part processing, electronic appliances, machinery manufacturing, aerospace satellites, meat processing plants, etc.

System Composition

- High-pressure cleaning system: High-pressure water pump, variable-frequency motor

- Control system: Variable-frequency electric control box, PLC + touch screen automatic control system

- Conveyor mesh belt chain and transmission system

- Fine filtration system

- Compressed air blowing system

- Drying system

Parameters of High-Pressure Cleaning System

- Pressure range: 50bar – 1500bar

- Flow rate range: 40 – 500L/min

- Customization available according to customer requirements.

Gedetailleerde productspecificatie

| Input Speed (r/min) | 1480 | Plunger Stroke (mm) | 120 | |||||

| Reduction Ratio (i) | 3.04 | Pump Speed (r/min) | 336 | |||||

| Vermogen (kW) | 110 | 132 | 160 | 200 | Plunger diameter (mm) | |||

| Nominale stroomsnelheid | Rated Discharge Pressure (Bar) | |||||||

| M³/H | L/ min | |||||||

| 11.7 | 195 | 280 | 330 | 400 | 450 | 45 | ||

| 14.4 | 240 | 220 | 270 | 330 | 360 | 50 | ||

| 17.7 | 295 | 190 | 220 | 270 | 300 | 55 | ||

| 21 | 350 | 160 | 190 | 230 | 250 | 60 | ||

| 24.9 | 415 | 130 | 160 | 190 | 210 | 65 | ||

| 28.8 | 480 | 110 | 130 | 170 | 190 | 70 | ||

| 30 | 500 | 10 | 12 | 16 | 18 | 75 | ||

Toepassingsgevallen

Automatic reactor cleaning

High-pressure cleaning of farms

Automatic assembly line cleaning

Metallurgical dephosphorization cleaning