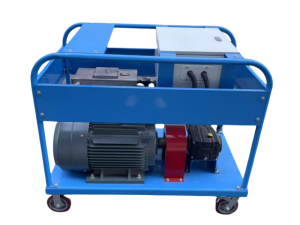

JMT-2-60L-500bar High-Pressure Washer

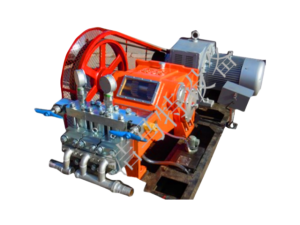

| 모델 | JMT-2 |

| 배출구 압력 | 500bar/7250psi |

| 물 유량 | 60L/min |

| 플런저 직경 | 26mm |

| 플런저 개수 | 3 |

| 입력 속도 | 1480r/min |

| Pump Speed | 405r/min |

| 플런저 스트로크 | 95mm |

| Motor Power | 55kw |

| 윤활 방법 | Forced Lubrication |

| Cooling Method | Water Cooling |

제품 특징 및 장점

1. 첨단 기술, 컴팩트한 구조, 부드럽고 안정적인 전송.

2. 안정적이고 신뢰할 수 있는 압력, 쉬운 조정.

3. 스테인리스 스틸, 충격에 강한 실리콘 오일, 압력 표시.

4. Forced lubrication on the power end reduces friction and improves lubricity, ensuring smooth and reliable transmission.

5. 견고하고 내구성이 뛰어난 단조 스테인리스 스틸 펌프 헤드.

6. 동기식 커플링으로 안정적인 작동을 보장합니다.

7. 연성 철로 제작된 고압 펌프 하우징으로 열 방출이 우수하고 질감이 단단하며 변형에 강합니다.

8. Three filters precisely filter incoming water impurities, extending the pump’s service life.

9. 유압 끝의 강제 수냉 시스템이 플런저 온도를 낮춥니다.

10. 전기 모터 또는 디젤 엔진 구동으로 제공됩니다.

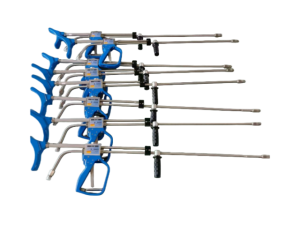

Applications Industry

1. Multi-application industrial cleaning applications, including heat exchanger tube cleaning, condenser tube cleaning, air preheater cleaning, condenser cleaning, pipeline cleaning, reactor cleaning, filter cleaning, reboiler cleaning, tank cleaning, and equipment surface cleaning.

2. Pipeline pressure testing, valve/hose pressure testing, pressure vessel and water pressure testing.

3. Cement plant pipeline cleaning, equipment surface grease removal, scale removal, and rotary kiln tail cleaning.

4. Construction industry: car/truck cleaning, mixing drum/tank cleaning, tar/cement/adhesive cleaning.

5. Food processing plants: mixing tank cleaning, grease/sludge/residue removal, evaporator/boiler cleaning.

6. Shipyard: rust removal, paint removal, hull cleaning, ship deck cleaning, fouling removal, and marine growth removal from ship bottoms.

7. Metallurgical equipment and metallurgical atomization.

8. Machinery manufacturing plants: vessel/pipe/tank cleaning, rust/scale removal.

9. Mining hydraulic support cleaning, remanufacturing, and more.

자세한 제품 사양

| Input Speed (r/min) | 1480 | Plunger Stroke (mm) | 95 | |||||

| Reduction Ratio (i) | 3.65 | Pump Speed (r/min) | 405 | |||||

| 전력(kw) | 30 | 37 | 45 | 55 | 75 | 90 | Plunger Diameter (mm) | |

| 정격 유량 | 정격 압력(바) | |||||||

| M³/H | L/ min | |||||||

| 2.4 | 40 | 370 | 460 | 22 | ||||

| 3 | 50 | 300 | 360 | 450 | 24 | |||

| 3.9 | 65 | 230 | 280 | 350 | 500 | 26 | ||

| 4.5 | 75 | 200 | 250 | 300 | 380 | 500 | 28 | |

| 5.1 | 85 | 170 | 220 | 260 | 340 | 450 | 500 | 30 |

| 6.12 | 102 | 150 | 180 | 220 | 280 | 360 | 430 | 32 |

| 8.1 | 135 | 110 | 140 | 170 | 210 | 280 | 330 | 35 |

| 10.2 | 170 | 90 | 110 | 140 | 170 | 240 | 280 | 40 |

| 12.9 | 215 | 70 | 90 | 110 | 130 | 180 | 200 | 45 |

| 15 | 250 | 60 | 70 | 90 | 120 | 160 | 190 | 50 |

적용 사례

Cement plant rotary kiln cleaning

Heat exchanger evaporative cooling cleaning

페인트 샵 청소