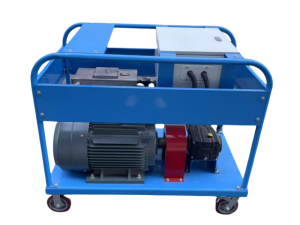

JMT-5-1500bar Diesel High Pressure Cleaner

| Model | JMT-5 |

| Outlet Pressure | 1500bar/14500psi |

| Water Flow Rate | 50L/min |

| Plunger Diameter | 22mm |

| Number of Plungers | 3 |

| Input Speed | 1480r/min |

| Pump Speed | 366r/min |

| Plunger Stroke | 120mm |

| Diesel Power | 238kw |

| Lubrication Method | Forced Lubrication |

| Cooling Method | Water Cooling |

Product Features and Advantages

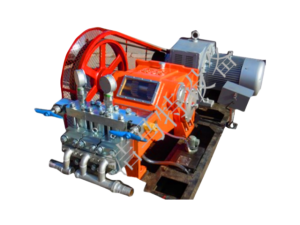

1. Advanced technology, compact structure, and smooth and reliable transmission.

2. Stable and reliable pressure, easy adjustment.

3. Stainless steel, shock-resistant silicone oil, and pressure display.

4. Forced lubrication on the power end reduces friction and improves lubricity, ensuring smooth and reliable transmission.

5. Forged stainless steel pump head, sturdy and durable.

6. Synchronous coupling ensures stable operation.

7. High-pressure pump housing made of ductile iron; excellent heat dissipation, hard texture, and resistant to deformation.

8. Three filters precisely filter incoming water impurities, extending the pump’s service life.

9. Forced water cooling system on the hydraulic end reduces plunger temperature.

10. Available with either electric motor or diesel engine drive.

Applications Industry

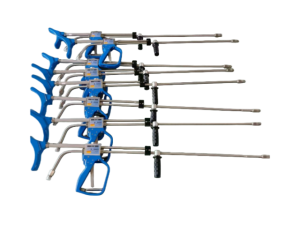

1. Multi-application industrial cleaning applications, including heat exchanger tube cleaning, condenser tube cleaning, air preheater cleaning, condenser cleaning, pipeline cleaning, reactor cleaning, filter cleaning, reboiler cleaning, tank cleaning, and equipment surface cleaning.

2. Pipeline pressure testing, valve/hose pressure testing, pressure vessel and water pressure testing.

3. Cement plant pipeline cleaning, equipment surface grease removal, scale removal, and rotary kiln tail cleaning.

4. Construction industry: car/truck cleaning, mixing drum/tank cleaning, tar/cement/adhesive cleaning.

5. Food processing plants: mixing tank cleaning, grease/sludge/residue removal, evaporator/boiler cleaning.

6. Shipyard: rust removal, paint removal, hull cleaning, ship deck cleaning, fouling removal, and marine growth removal from ship bottoms.

7. Metallurgical equipment and metallurgical atomization.

8. Machinery manufacturing plants: vessel/pipe/tank cleaning, rust/scale removal.

9. Mining hydraulic support cleaning, remanufacturing, and more.

Application Cases

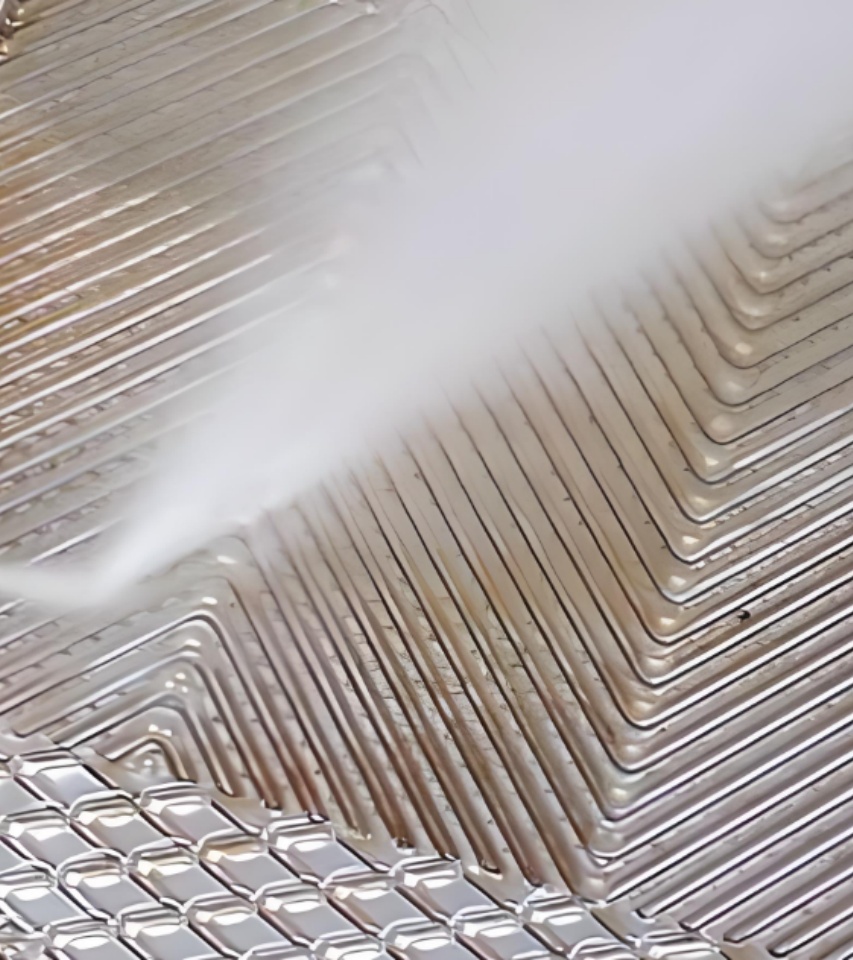

Plate heat exchanger cleaning

Condensing heat exchanger cleaning

Ship paint removal

Detailed Product Specification

| Input Speed (r/min) | 1480 | Plunger Stroke (mm) | 120 | ||||

| Reduction Ratio (i) | 4.04 | Pump Speed (r/min) | 336 | ||||

| Power (kw) | 90 | 110 | 132 | 160 | 200 | Plunger Diameter (mm) | |

| Rated Flow Rate | Rated Pressure (Bar) | ||||||

| M³/H | L/ min | ||||||

| 2.4 | 40 | 1150 | 1400 | 1500 | 20 | ||

| 3 | 50 | 950 | 1200 | 1400 | 1500 | 22 | |

| 3.6 | 60 | 800 | 1000 | 1150 | 1400 | 24 | |

| 4.2 | 70 | 700 | 850 | 1000 | 1200 | 1500 | 26 |

| 4.8 | 80 | 560 | 700 | 850 | 1000 | 1400 | 28 |

| 5.58 | 93 | 500 | 600 | 700 | 900 | 1200 | 30 |

| 6.06 | 110 | 400 | 500 | 600 | 800 | 1000 | 32 |