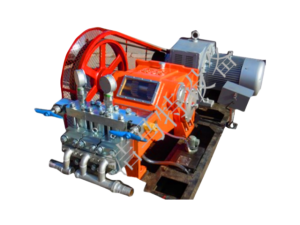

JMT-2-180 Bar Fixed Pipe Dredging Machine

| Model | JMT-2 |

| Outlet Pressure | 180bar/2600psi |

| Water Flow Rate | 135L/min |

| Plunger Diameter | 50mm |

| Number of Plungers | 3 |

| Input Speed | 1480r/min |

| Pump Speed | 1450r/min |

| Plunger Stroke | 28mm |

| Engine Power | 62kw/85HP |

| Water Inlet Size | G2-inch |

Working Principles

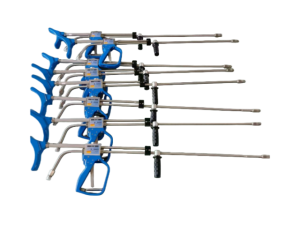

The high-pressure pump generates a high-pressure water jet. Connect the pipe unclogging nozzle to the pump via a high-pressure hose and place the nozzle directly inside the pipe to be unblocked.

As the high-pressure pump operates, the reaction force generated by the high-pressure water ejected from the rear of the nozzle rapidly pushes the nozzle forward. High-pressure water jets generated by the nozzle’s front and rear nozzle holes quickly clean the pipe.

As the pipe collector pulls the nozzle back, the high-pressure water flow flushes dirt out of the pipe bundle.

Applications: Used for unclogging and clearing clogged pipes in municipal, residential, and industrial parks.

Product Features and Advantages

1. Advanced technology, compact structure, and smooth and reliable transmission.

2. Stable and reliable pressure, easy adjustment.

3. Stainless steel, shock-resistant silicone oil, and pressure display.

4. Forced lubrication on the power end reduces friction and improves lubricity, ensuring smooth and reliable transmission.

5. Forged stainless steel pump head, sturdy and durable.

6. Synchronous coupling ensures stable operation.

7. High-pressure pump housing made of ductile iron; excellent heat dissipation, hard texture, and resistant to deformation.

8. The equipment is equipped with a filter to precisely filter impurities in the incoming water, which is beneficial to extending the service life of the water pump

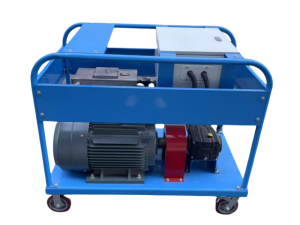

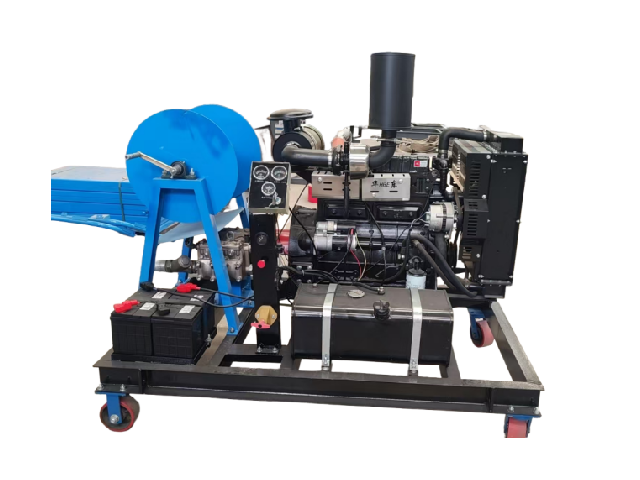

9. Available with either electric motor or diesel engine drive.

Applications Industry

1. Multi-application cleaning, including residential property pipe cleaning.

2. Multi-application cleaning, including municipal pipe cleaning and unclogging.

3. Multi-application cleaning, including diversion tunnel pipe cleaning.

4. Multi-application cleaning, including tunnel and culvert pipe cleaning.

5. Hull cleaning, deck cleaning, decontamination, and marine growth removal from ship bottoms.

6. Metallurgical equipment and metallurgical atomization.

7. Machinery manufacturing plants, including vessel/pipeline/rust/scale cleaning.

8. Cement plant pipe cleaning, removing grease and dirt from equipment surfaces.

9. Mining hydraulic support cleaning, remanufacturing, etc.

Detailed Product Specification

| Input Speed (r/min) | 1480 | Plunger Stroke (mm) | 95 | |||||

| Reduction Ratio (i) | 3.65 | Pump Speed (r/min) | 1405 | |||||

| Power (kw) | 30 | 37 | 45 | 55 | 75 | 90 | Plunger diameter (mm) | |

| Rated Flow Rate | Rated Discharge Pressure (Bar) | |||||||

| M³/H | L/ min | |||||||

| 2.4 | 40 | 370 | 460 | 22 | ||||

| 3 | 50 | 300 | 360 | 450 | 24 | |||

| 3.9 | 65 | 230 | 280 | 350 | 500 | 26 | ||

| 4.5 | 75 | 200 | 250 | 300 | 380 | 500 | 28 | |

| 5.1 | 85 | 170 | 220 | 260 | 340 | 450 | 500 | 30 |

| 6.12 | 102 | 150 | 180 | 220 | 280 | 360 | 430 | 32 |

| 8.1 | 135 | 110 | 140 | 170 | 210 | 280 | 330 | 35 |

| 10.2 | 170 | 90 | 110 | 140 | 170 | 240 | 280 | 40 |

| 12.9 | 215 | 70 | 90 | 110 | 130 | 180 | 200 | 45 |

| 15 | 250 | 60 | 70 | 90 | 120 | 160 | 190 | 50 |

Application Cases

Cement pipe cleaning

Sewer pipe cleaning

Square trench cleaning