Jie Matt 柔軟で強力な高圧洗浄機

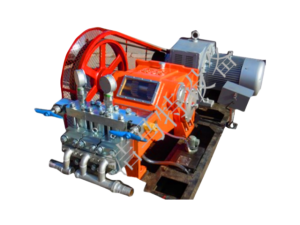

- ドイツKAMTA社のコア技術

- 360°死角のない洗浄が可能

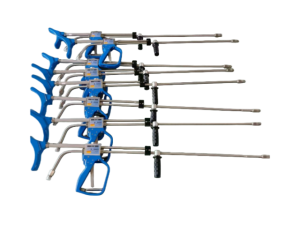

- 異なるタイプのノズルのマッチングに対応(扇形、回転式など

- 様々な産業シーンに適した豊富な構成

- 高度な自動化、システム全体がカスタマイズに対応

メリット

洗浄効率と耐久性を保証する、成長とともに成長する将来性のあるソリューション

定員

最大圧力3000バール、最大流量1480 L/minで、頑固な汚れや大規模なパイプラインの洗浄ニーズにも容易に対応します。

システム

低騒音で安定稼動し、長時間の高負荷運転をサポートし、機器の寿命を延ばします。

モジュール

圧力と流量をワンクリックで切り替え、油田注水、石油化学パイプライン、都市下水処理など多様なシーンに対応。

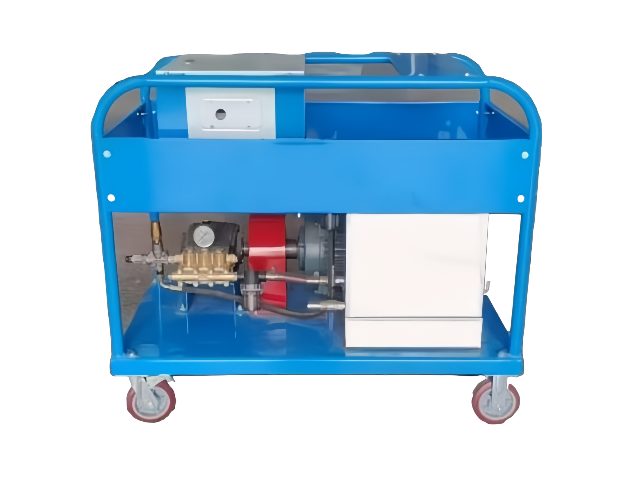

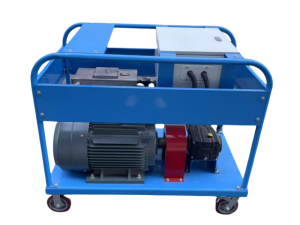

売れ筋モデル

事業範囲

当社は2008年9月10日に設立され、高圧洗浄機の設計・製造を行っています。当社の装置は、石油、化学、鉄鋼、海運、水力発電、砂糖、石炭、鉱業、建設、自動車製造、自治体の衛生管理、パイプラインの圧力検査など、あらゆる産業で活躍しています。

主な製品超高圧洗浄機、高圧プランジャー、ウォーターポンプ、パイプ洗浄機、高圧温水洗浄機、高圧水粗面化機、圧力テストポンプ、高圧グラウティングポンプ、ウォータージェット切断機と付属品など。

Jie Matt高圧洗浄液を選ぶ理由

ジメイトは、産業洗浄の厳しい要求に応えるために、高級部品、包括的なサービス、革新的な機能を組み合わせた一連の利点で際立っています。

信頼性の高いプレミアム・コンポーネント

ドイツ語 - 中核部品:超高圧ポンプと三国回転ノズルを搭載。高い洗浄効率と長寿命を実現し、製鉄所の洗浄作業で安定した性能を発揮します。

プランジャーポンプ技術を採用し、圧力範囲は500~3000Barまで調整可能で、油汚れ、錆、コンクリートなど様々な頑固な汚染物質に適している。効率は手作業の5~8倍。

手間いらずのワンストップサービス

総合的なサービス:高圧水鉄砲、ノズル、アフターサービスを提供。機器供給からアフターメンテナンスまで、ワンストップサービスでお客様の不安を解消します。

環境に優しいオペレーション

純水洗浄:化学汚染のない純水で洗浄を行い、グリーン産業基準に適合。また、IoTモジュールと統合され、水圧と流量をリアルタイムで調整し、環境に配慮しながら洗浄プロセスを最適化します。

インテリジェントな省エネ設計:

- 周波数変換制御:作業状況に応じて水圧と流量を自動調整し、水と電気の消費量を30%で削減。

- 循環システム:廃水濾過と再利用率は80%で、環境保護規則に合致している。

費用対効果の高い直販

工場直接供給:河南吉瑪徳は高圧スケール除去ポンプのメーカーとして、研究開発からアフターサービスまで一貫したサービスを提供しています。中間マージンをカットし、15% - 20%の設備価格を削減し、費用対効果の高いソリューションを提供します。

特定のニーズに合わせたカスタマイズ・ソリューション

テーラード・デザイン:使用条件に応じて出力、圧力、耐蝕材質(セラミックプランジャー等)をカスタマイズ。また、操作教育やメンテナンスサポートも行っております。技術的なご相談や故障対応など、いつでもご連絡ください。

- フル・シーン・カスタマイズ・サービス:高圧洗浄機のカスタムメーカーとして、ジメイトは提供します。

- 機能拡張:回転ノズル、温水モジュール(80℃)、防爆型。

- 素材のアップグレード:316Lステンレス製ポンプ本体、タングステンカーバイトコーティングノズル、耐酸性、耐アルカリ性。

インテリジェントなIoT管理

リアルタイム・モニタリングタッチスクリーンで10種類の洗浄モードをプリセットし、ワンクリックで切り替え可能。 圧力、温度、機器の健康状態をリアルタイムで監視し、95%以上の故障警告精度を実現。

仕様

| 流量(L/min) | 圧力 (bar) | モーター出力(KW) | ガソリンエンジン出力(HP) | ディーゼルエンジン出力(HP) |

| 15 | 200 | 5.5 | 13 | 15 |

| 15 | 250 | 7.5 | 15 | 18 |

| 23 | 350 | 15 | 24 | 28 |

| 23 | 500 | 22 | 37 | 36 |

| 30 | 500 | 30 | 45 | |

| 30 | 600 | 37 | 85 | |

| 20 | 800 | 30 | 58 | |

| 20 | 1000 | 37 | 85 |

パラメータはニーズに応じてカスタマイズ可能

高圧ウォータージェット洗浄アプリケーション

産業機器クリーニング

石油化学・エネルギー部門 貯蔵タンクや反応釜の内壁に付着した油汚れの除去に使用される。この方法は化学洗浄に代わるもので、環境汚染の原因となる有害な化学物質を使用しないため、環境に優しい。

機械製造: エンジン部品の脱脂と溶接残渣の洗浄を実現し、その清浄度はミクロン・レベルに達している。

自治体および環境保護分野

道路整備: マーキング除去の効率は毎時100平方メートルに達し、アスファルト舗装の非破壊補修を可能にし、路面の完全性と耐用年数を効果的に維持する。

廃棄物処理: 焼却炉や搬送ステーションに高圧滅菌・洗浄を施すことで、細菌の繁殖を徹底的に排除し、病気の蔓延を防ぐことができる。

造船・運輸工学

船体の除塵: 酸化被膜をSa2.5レベルまで剥離できるため、塗膜の寿命が3倍に延び、再塗装の頻度と関連コストを大幅に削減できる。

鉄道輸送: 列車の外殻や線路上の堆積物を洗浄し、鉄道輸送システムの性能を向上させ、外観を美しくする。

建設と農業のシナリオ

コンクリートの改修: 床面の粗面化と旧塗膜の剥離を行い、新しい塗料や素材の密着性を高める。

農場の清掃 高圧温水洗浄を採用し、殺菌率は99%で、関連衛生基準を満たし、清潔で安全な飼育環境を確保する。

どのマシンがお客様のビジネスに適しているか、判断にお困りですか?

今すぐEメールをお送りください。私たちの装置が実際にどのように機能するのかをお見せし、計画のお手伝いをいたします。お客様のオペレーションを清潔、安全、効率的に保つソリューションを見つけましょう。

製品用途

ボートクリーニング

フォークリフト清掃

壁のクリーニング

パイプ洗浄

我々は高品質の製品と価格競争力とあなたのためのオンタイムデリバリーをお約束いたします。私たちは、お客様との長期ビジネスを確立されています。私達のプロダクトの何れかのモデルに興味がある場合は、お問い合わせは、自由にしてくださいを参照してください。