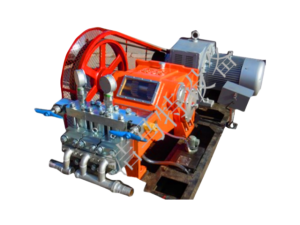

Sistema di pulizia automatico della serie JMT

| Modello | JMT-7 |

| Pressione di uscita | 200bar/7250psi |

| Portata d'acqua | 480L/min |

| Diametro dello stantuffo | 70 mm |

| Numero di pistoni | 3 |

| Velocità di ingresso | 1480r/min |

| Velocità della pompa | 366 giri/min |

| Corsa dello stantuffo | 120 mm |

| Potenza del motore | 200KW |

| Metodo di lubrificazione | Lubrificazione forzata |

| Metodo di raffreddamento | Raffreddamento ad acqua |

Caratteristiche e vantaggi del prodotto

1. Tecnologia avanzata, struttura compatta e trasmissione fluida e affidabile.

2. Pressione stabile e affidabile, facile da regolare.

3. Acciaio inossidabile, olio di silicone resistente agli urti e display della pressione.

4. La lubrificazione forzata sull'estremità di potenza riduce l'attrito e migliora la lubrificazione, garantendo una trasmissione fluida e affidabile.

5. Testa della pompa in acciaio inox forgiato, robusta e durevole.

6. L'accoppiamento sincrono garantisce un funzionamento stabile.

7. Alloggiamento della pompa ad alta pressione in ghisa duttile; eccellente dissipazione del calore, struttura dura e resistente alla deformazione.

8. L'apparecchiatura è dotata di un filtro per filtrare con precisione le impurità presenti nell'acqua in entrata, a vantaggio del prolungamento della durata della pompa dell'acqua.

9. Disponibile con motore elettrico o motore diesel.

Descrizione dell'apparecchiatura

Questa apparecchiatura è un linea di pulizia e asciugatura a spruzzo passante progettato per soddisfare le crescenti richieste dell'industria manifatturiera di standard di pulizia più elevati e di una maggiore produttività. Integra tecnologie mature come la pulizia a spruzzo, l'asciugatura a tunnel e l'asciugatura a circolazione interna. Le sue caratteristiche principali sono le seguenti:

- Adotta una trasmissione a catena in acciaio inox ed è dotata di un'area di spruzzatura a bassa pressione, di un'area di lavaggio ad alta pressione, di un'area di taglio ad acqua a lama d'aria, di un'area di asciugatura a circolazione interna a tunnel e di un'area di carico/scarico, con un elevato grado di automazione.

- Per rispondere alle caratteristiche dei pezzi con tipi multipli, forme complesse e strutture con fori profondi o porosi, durante il processo di pulizia e asciugatura viene impostata una funzione di rotazione a bassa velocità per garantire una pulizia e un'asciugatura complete.

- Adatta agli scenari di produzione di utensili metallici e apparecchi elettrici di ferramenta, è un'apparecchiatura di pulizia automatizzata ideale per i produttori del settore.

Scopo e campi di applicazione

- Scopo: Rimuove le impurità come il liquido da taglio, le bave, lo sporco, le macchie d'olio e i trucioli metallici attaccati alla superficie dei pezzi.

- Campi di applicazione: Produzione di automobili, lavorazione di parti in alluminio, apparecchi elettronici, produzione di macchinari, satelliti aerospaziali, impianti di lavorazione della carne, ecc.

Composizione del sistema

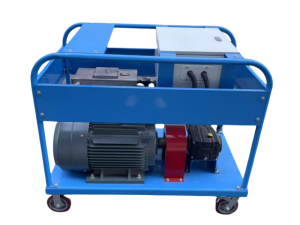

- Sistema di pulizia ad alta pressione: Pompa dell'acqua ad alta pressione, motore a frequenza variabile

- Sistema di controllo: Quadro elettrico a frequenza variabile, sistema di controllo automatico PLC + touch screen

- Catena e sistema di trasmissione del nastro trasportatore

- Sistema di filtrazione fine

- Sistema di soffiaggio ad aria compressa

- Sistema di asciugatura

Parametri del sistema di pulizia ad alta pressione

- Intervallo di pressione: 50bar - 1500bar

- Gamma di portata: 40 - 500L/min

- Personalizzazione disponibile in base ai requisiti del cliente.

Specifiche di prodotto dettagliate

| Velocità di ingresso (r/min) | 1480 | Corsa del pistone (mm) | 120 | |||||

| Rapporto di riduzione (i) | 3.04 | Velocità della pompa (r/min) | 336 | |||||

| Potenza (kw) | 110 | 132 | 160 | 200 | Diametro dello stantuffo (mm) | |||

| Portata nominale | Pressione nominale di scarico (Bar) | |||||||

| M³/H | L/ min | |||||||

| 11.7 | 195 | 280 | 330 | 400 | 450 | 45 | ||

| 14.4 | 240 | 220 | 270 | 330 | 360 | 50 | ||

| 17.7 | 295 | 190 | 220 | 270 | 300 | 55 | ||

| 21 | 350 | 160 | 190 | 230 | 250 | 60 | ||

| 24.9 | 415 | 130 | 160 | 190 | 210 | 65 | ||

| 28.8 | 480 | 110 | 130 | 170 | 190 | 70 | ||

| 30 | 500 | 10 | 12 | 16 | 18 | 75 | ||

Casi di applicazione

Pulizia automatica del reattore

Pulizia ad alta pressione delle aziende agricole

Pulizia automatica della linea di assemblaggio

Pulizia metallurgica di disfosforilazione