Jie Matt Industrial & Compact High-pressure pump

- German KAMTA core technology

- Precision manufacturing of core components

- 30KW to 90KW power

- Rich configurations, suitable for various industrial scenarios

- Green and environmentally friendly design

- Supports a variety of media such as clean water and thin oil

Benefits

A future-proof solution that grows with you – ensure cleaning efficiency and durability.

Capacity

Plunger diameter 22mm-45mm optional, flow rate 2.4m³/h to 10.2m³/h, pressure up to 500Bar, meeting the full scene requirements from clean water/thin oil delivery high-pressure pump to high-strength cleaning.

System

Runs stably with low noise, supports long-term high-intensity operations, and extends the service life of the equipment.

Eco-friendly

No chemical agents are required, only power and water are required to operate, which greatly reduces environmental pollution and operation and maintenance costs.

Hot Selling Models

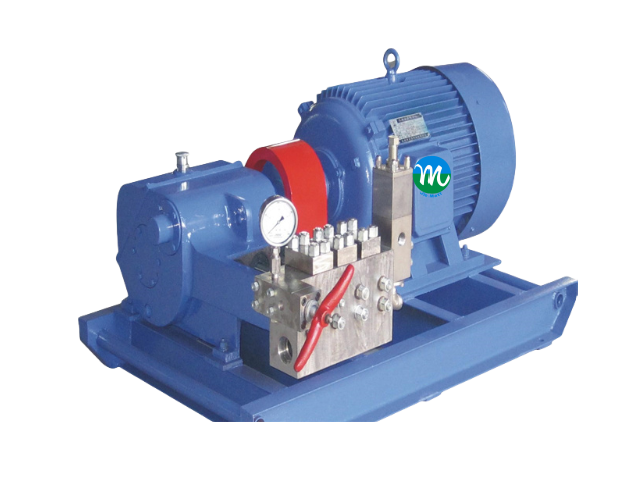

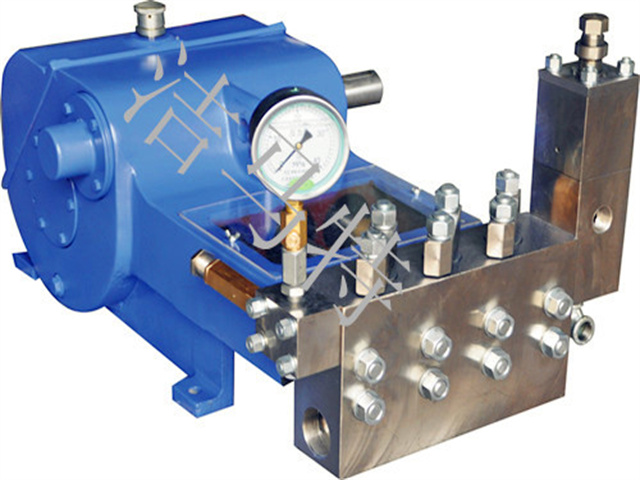

Jie Matt -1 Series

High-pressure water mist pump

- High pressure up to 500Bar

- Rated flow rate 2.4-10.2 m³/h

- Quickly covers the fire source

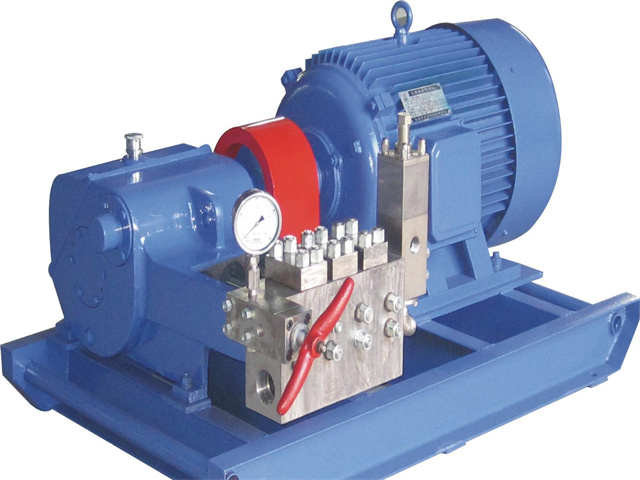

Jie Matt -2 Series

Seawater desalination pump

- Pressure up to 500Bar

- Power from 30KW to 90KW

- Pumping seawater, supporting reverse osmosis system

Jie Matt -6 Series

High-pressure cooling pump

- Speed: 1480 min⁻¹

- Pressure: 1000Bar

- Continuous and stable operation in high temperature environment (≤150℃)

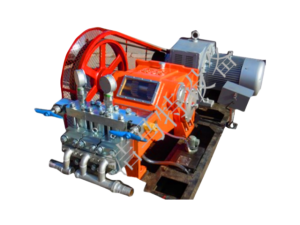

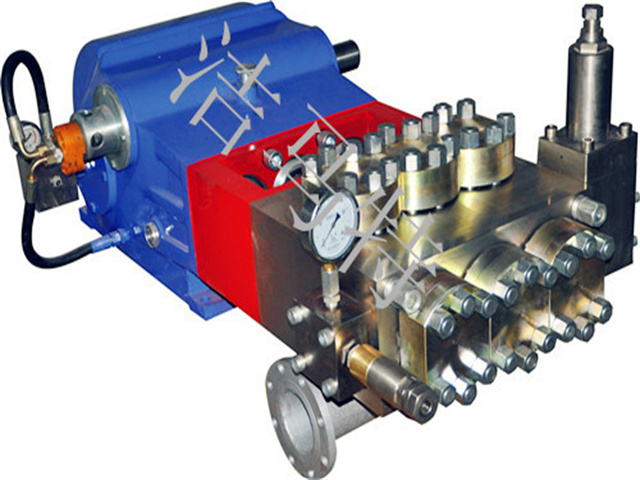

Jie Matt -3 Series

Powder metallurgy pump

- Pressure up to 500Bar

- Power from 30KW to 90KW

- Metal powder molding provides a stable pressure source to ensure product density and consistency

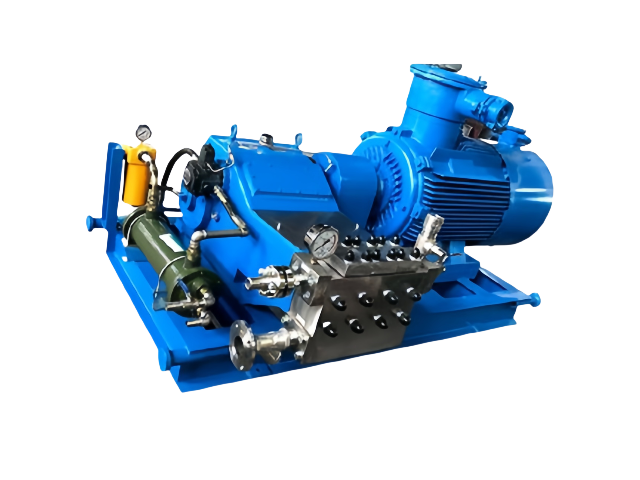

Jie Matt -5 Series

Spunlace nonwoven pump

- Pressure up to 500Bar

- Power from 30KW to 90KW

- Rated Flow: 40-110 L/min

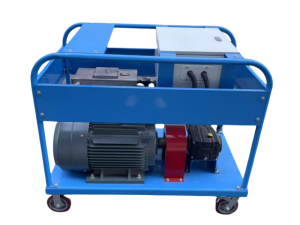

Jie Matt -6 Series

Reverse osmosis pump

- Direct-drive and belt-driven

- Hot water machine and cold water machine

- Small size, high power, easy to move

Jie Matt -6 Series

Water dephosphorization pump

- Flow rate up to 38.3m³/h

- 160-250KW high power

- Pressure 125-980Bar

- Quickly strip the oxide layer on the steel surface

Jie Matt -6 Series

Pipeline pressure testing pump

- Pressure: 1500-3000Bar

- Supports a variety of media such as clean water and thin oil

- Accurately verify the sealing of oil and gas pipelines to prevent leakage risks

Jie Matt -6 Series

Oilfield water injection pump

- Power 90-300kW

- Oil pumps using variable frequency speed regulation technology reduce energy consumption by 25%

- Applicable to low permeability reservoir development

Our Business Scope

Founded on September 10, 2008, we design and manufacture high-pressure cleaning machines. Our equipment works across industries: petroleum, chemical, steel, shipping, hydropower, sugar, coal, mining, construction, auto manufacturing, municipal sanitation, pipeline pressure testing, and more.

Our main products: Ultra-high pressure cleaning machine, high pressure plunger, water pump, pipe cleaning machine, high pressure hot water cleaning machine, high pressure water roughening machine, pressure test pump, high pressure grouting pump, water jet cutting machine and accessories, etc.

Why Choose Jie Matt High Pressure Pump?

As the core power equipment in the industrial field, high-pressure pump launched by Henan Jiematt has become the equipment for fire protection, shipbuilding, energy, construction and other industries with the support of German Womar technology, compact high-pressure pump design, energy and green environmental protection characteristics.

Product line covers diversified needs such as pipeline pressure test high-pressure pumps, ship rust removal high-pressure pumps, cement plant maintenance high-pressure pumps, etc., fully empowering the field of industrial cleaning and fluid transportation.

Multi-industry application scenarios: accurately match needs and improve efficiency

Seawater desalination high-pressure pump: pumping seawater, supporting the stable operation of the reverse osmosis system, and promoting the sustainable development of freshwater resources.

Ship rust removal high-pressure pump: high-pressure water flow quickly strips off hull rust and attachments, extends the service life of the ship, and replaces traditional chemical cleaning.

Pipeline pressure test high-pressure pump: adapt to media such as clean water and thin oil, accurately detect pipeline sealing, and ensure the transportation of oil, gas, chemicals, etc.

Industrial maintenance cleaning:

Cement plant maintenance high-pressure pump: remove kiln agglomeration and dust deposition to improve equipment operation efficiency.

Starch factory cleaning high-pressure pump: clean production line residues, avoid biological contamination, and ensure food-grade hygiene standards.

Customized service: design on demand, direct sales nationwide

Henan Jiemate provides “high-pressure pump nationwide direct sales” service, supporting customers to customize parameter combinations according to actual working conditions. For example:

- Small scene: choose 3m³/h flow, 300Bar pressure model, suitable for community fire protection or light pipeline pressure testing.

- Large demand: 10.2m³/h flow, 240Bar pressure high-performance pump, specially designed for ship engineering or seawater desalination projects.

All products support fast delivery, 24-hour hotline (180-0385-3609) provides technical consultation and quotation services, helping enterprises reduce costs and increase efficiency.

Why Choose Jie Matt High Pressure Cleaning Solution?

Jiemate stands out with a suite of advantages tailored to meet the rigorous demands of industrial cleaning, combining premium components, comprehensive services, and innovative features.

Premium Components for Reliability

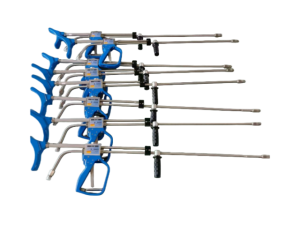

German – Core Parts: Equipped with ultra – high – pressure pumps and tri-nation rotating nozzles. These key components guarantee high cleaning efficiency and long – lasting durability, ensuring stable performance in steel mill cleaning tasks.

Adopting plunger pump technology, the pressure range is adjustable from 500 – 3000Bar, suitable for various stubborn pollutants such as oil stains, rust, and concrete. The efficiency is 5 – 8 times higher than that of manual work.

One-Stop Service for Hassle-Free Experience

Comprehensive Offerings: We provide high – pressure water guns, nozzles, and after – sales technical support. This one-stop service eliminates your worries, covering from equipment supply to subsequent maintenance.

Environmental-Friendly Operation

Pure Water Cleaning: Conducted with pure water without chemical pollution, complying with green industrial standards. Also, integrated with IoT modules to adjust water pressure and flow in real-time, optimizing cleaning processes while being eco-conscious.

Intelligent Energy – Saving Design:

- Frequency Conversion Control: Automatically adjusts water pressure and flow according to working conditions, reducing water and electricity consumption by 30%.

- Circulation System: The wastewater filtration and reuse rate is 80%, in line with environmental protection regulations.

Cost-Effective Direct Sales

Factory-Direct Supply: As a manufacturer of high-pressure descaling pumps, Henan Jiemate offers self-delivered services from R & D to after – sales. Cutting out middlemen, we reduce equipment prices by 15% – 20%, providing cost-effective solutions.

Customized Solutions for Specific Needs

Tailored Design: Customize power, pressure, and corrosion-resistant materials (such as ceramic plungers) according to working conditions. We also offer operation training and maintenance support. For technical consultation or fault handling, contact us anytime.

- Full-Scene Customization Service: As a custom manufacturer of high – pressure cleaning equipment, Jiemate provides:

- Function Expansion: Rotating nozzles, hot water modules (80℃), explosion – proof models.

- Material Upgrade: 316L stainless steel pump bodies, tungsten carbide coated nozzles, resistant to acid and alkali corrosion.

Intelligent IoT Management

Real – time monitoring:A touch screen presets 10 cleaning modes for one – click switching. Real – time monitoring of pressure, temperature, and equipment health status, with a fault warning accuracy of over 95%.

Specification

| Nominal Flow | Plunger Diameter | Plunger Stroke | Pump Speed | Rated Discharge Pressure | |||

| m³/h | L/min | mm | mm | min⁻¹ | Bar | ||

| 2.4 | 40 | 22 | 100 | 332 | 1000 | ||

| 2.7 | 45 | 24 | 100 | 332 | 850 | 1000 | 800 |

| 3.12 | 52 | 26 | 100 | 332 | 750 | 900 | 1000 |

| 3.6 | 60 | 28 | 100 | 332 | 650 | 800 | 9550 |

| 4.2 | 70 | 30 | 100 | 332 | 600 | 700 | 850 |

Parameters can be customized according to your needs.

Jie Matt Industrial High Pressure Pump Application

Industrial high-pressure pumps play crucial roles in various sectors due to their ability to generate and control high-pressure fluid flows. Here are some common applications:

Oil and Gas Industry

- Well Stimulation

- Hydraulic Fracturing (Fracking): High-pressure pumps are used to inject a mixture of water, sand, and chemicals into oil and gas wells at extremely high pressures (typically ranging from 10,000 to 20,000 psi). This process fractures the rock formation, allowing the trapped oil or gas to flow more freely into the wellbore for extraction.

- Well Cleaning and Maintenance: They are employed to clean out debris, scale, and other obstructions from wells. High-pressure water jets can be used to remove deposits that may impede the flow of hydrocarbons.

- Pipeline Transportation

- Pipeline Testing: Before a new pipeline is put into operation, high-pressure pumps are used to conduct hydrostatic tests. These tests involve filling the pipeline with water and pressurizing it to a level higher than the expected operating pressure to check for leaks and structural integrity.

- Pipeline Pigging Assistance: In some cases, high-pressure pumps can be used to assist in the movement of pipeline pigs (devices used for cleaning, inspecting, or maintaining pipelines). The high-pressure fluid can help push the pig through the pipeline, especially in long or complex pipeline systems.

Water and Wastewater Treatment

- Reverse Osmosis (RO) Systems

- High-pressure pumps are essential for reverse osmosis desalination plants. They pressurize the feed water (usually seawater or brackish water) to force it through a semi-permeable membrane, which removes salts and other impurities. The pressure required can be in the range of 800 to 1200 psi, depending on the salinity of the feed water and the design of the RO system.

- Sludge Dewatering

- In wastewater treatment plants, high-pressure pumps can be used in processes like filter press feeding. They pump the sludge into filter presses at high pressure, which helps in separating the liquid and solid phases of the sludge, reducing the volume of the sludge for disposal or further treatment.

- High-Pressure Washing for Treatment Facilities

- To clean tanks, reactors, and pipelines within water and wastewater treatment plants, high-pressure pumps are used to generate high-pressure water streams. These streams can effectively remove accumulated debris, biofilms, and deposits, ensuring the proper functioning of the treatment equipment.

Manufacturing and Processing Industries

- Metal Processing

- Steel Mill Descaling: In steel production, high-pressure pumps supply water at pressures up to 2000 psi or more to remove scale (oxide layers) from the surface of hot steel slabs, billets, or coils. This improves the quality of the final steel product and helps in subsequent processing steps like rolling.

- Die Casting: High-pressure pumps are used to provide the necessary pressure for injecting molten metal into dies in die-casting processes. The precise control of pressure is crucial for achieving accurate and high-quality castings.

- Food and Beverage Industry

- Bottle Washing: In bottling plants, high-pressure pumps create high-pressure water jets to clean glass or plastic bottles before filling. This ensures that the bottles are free from contaminants.

- Processing Equipment Cleaning: For cleaning large-scale food processing equipment such as mixers, reactors, and conveyor belts, high-pressure pumps are used. The high-pressure fluid can reach into crevices and remove food residues, bacteria, and other contaminants, ensuring food safety and compliance with hygiene standards.

Construction and Mining

- Tunnel Boring and Excavation

- Soil Stabilization: High-pressure pumps are used to inject grout (a mixture of cement, water, and other additives) into the soil around tunnel boring machines or excavation sites. The high pressure helps in distributing the grout evenly, strengthening the soil and preventing collapse.

- Rock Drilling and Cutting Assistance: In some rock-drilling operations, high-pressure water jets can be used in conjunction with mechanical drilling. The high-pressure water helps in breaking up the rock, reducing the wear on drilling equipment and improving the drilling rate.

- Concrete Construction

- Shotcrete Application: High-pressure pumps are used to spray shotcrete (a mixture of cement, aggregates, and water) onto surfaces. In tunnel linings, slope stabilization, or repair work, the high-pressure application ensures good adhesion and compaction of the shotcrete, resulting in a strong and durable concrete layer.

- Concrete Demolition: High-pressure water jets generated by these pumps can be used for concrete demolition. The high-pressure stream can break up concrete structures without the need for large-scale mechanical crushing, which is beneficial in situations where precision and reduced noise and dust are required, such as in urban construction or historical building renovation.

Aerospace and Automotive

- Aerospace Component Cleaning

- In the aerospace industry, high-pressure pumps are used to clean aircraft components, such as engine parts, wings, and fuselage sections. The high-pressure fluid can remove contaminants like grease, oil, and metal shavings, ensuring the components meet strict safety and performance standards.

- Automotive Paint and Coating

- Paint Booth Cleaning: High-pressure pumps are used to clean automotive paint booths. The high-pressure water can remove overspray, paint residues, and other contaminants from the booth surfaces, maintaining a clean environment for painting vehicles.

- Component Washing: For cleaning automotive engine components, transmission parts, and other critical parts before assembly or after machining, high-pressure pumps provide an effective way to remove dirt, metal chips, and cutting fluids.

Need help figuring out which machine is right for your business?

Send an email to us today. We’ll show you how our equipment works in action and help with the plan. Let’s find the solution that keeps your operations clean, safe, and efficient.

Products Applications

Rust cleaning

Powder metallurgy

Pipe pressure test

Concrete cleaning

We are committed to producing the best quality products at the most competitive prices. Therefore, we sincerely invite all interested companies to contact us for more information.