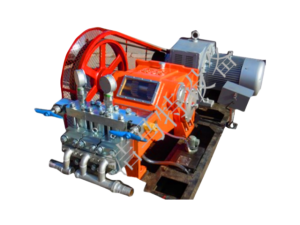

Système de nettoyage automatique de la série JMT

| Modèle | JMT-7 |

| Pression de sortie | 200bar/7250psi |

| Débit d'eau | 480L/min |

| Diamètre du piston | 70 mm |

| Nombre de poussoirs | 3 |

| Vitesse d'entrée | 1480r/min |

| Vitesse de la pompe | 366r/min |

| Course du piston | 120 mm |

| Puissance du moteur | 200KW |

| Méthode de lubrification | Lubrification forcée |

| Méthode de refroidissement | Refroidissement par eau |

Caractéristiques et avantages du produit

1. Technologie avancée, structure compacte, transmission souple et fiable.

2. Pression stable et fiable, réglage facile.

3. Acier inoxydable, huile de silicone résistante aux chocs et affichage de la pression.

4. La lubrification forcée de la partie motrice réduit les frottements et améliore le pouvoir lubrifiant, ce qui garantit une transmission souple et fiable.

5. Tête de pompe en acier inoxydable forgé, robuste et durable.

6. L'accouplement synchrone assure un fonctionnement stable.

7. Le corps de la pompe haute pression est en fonte ductile ; excellente dissipation de la chaleur, texture dure et résistante à la déformation.

8. L'équipement est équipé d'un filtre qui filtre avec précision les impuretés présentes dans l'eau entrante, ce qui permet de prolonger la durée de vie de la pompe à eau.

9. Disponible avec un moteur électrique ou un moteur diesel.

Description de l'équipement

Cet équipement est un ligne de nettoyage et de séchage par pulvérisation conçu pour répondre aux exigences croissantes de l'industrie manufacturière en matière de normes de propreté plus strictes et de rendement de nettoyage plus élevé. Il intègre des technologies éprouvées telles que le nettoyage par pulvérisation, le séchage en tunnel et le séchage par circulation interne. Ses principales caractéristiques sont les suivantes

- Il est équipé d'une zone de pulvérisation à basse pression, d'une zone de lavage à haute pression, d'une zone de découpe de l'eau par lame d'air, d'une zone de séchage à circulation interne de type tunnel et d'une zone de chargement/déchargement, avec un degré élevé d'automatisation.

- Pour répondre aux caractéristiques des pièces à usiner de types multiples, de formes complexes et de structures poreuses ou à trous profonds, une fonction de rotation à faible vitesse est mise en place pendant le processus de nettoyage et de séchage afin de garantir un nettoyage et un séchage complets.

- Adapté aux scénarios de production d'ustensiles métalliques et d'appareils électriques, c'est un équipement de nettoyage automatisé idéal pour les fabricants concernés.

Objectif et champs d'application

- Objectif: Elimine les impuretés telles que le liquide de coupe, les bavures, la saleté, les taches d'huile et les copeaux métalliques attachés à la surface des pièces.

- Champs d'application: Fabrication d'automobiles, traitement de pièces en aluminium, appareils électroniques, fabrication de machines, satellites aérospatiaux, usines de transformation de la viande, etc.

Composition du système

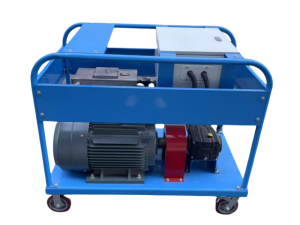

- Système de nettoyage à haute pression : Pompe à eau à haute pression, moteur à fréquence variable

- Système de contrôle : Boîtier de commande électrique à fréquence variable, système de commande automatique PLC + écran tactile.

- Chaîne et système de transmission de la bande à mailles du convoyeur

- Système de filtration fine

- Système de soufflage d'air comprimé

- Système de séchage

Paramètres du système de nettoyage à haute pression

- Gamme de pression : 50bar - 1500bar

- Plage de débit : 40 - 500L/min

- Personnalisation possible selon les exigences du client.

Spécification détaillée du produit

| Vitesse d'entrée (r/min) | 1480 | Course du piston (mm) | 120 | |||||

| Taux de réduction (i) | 3.04 | Vitesse de la pompe (r/min) | 336 | |||||

| Puissance (kw) | 110 | 132 | 160 | 200 | Diamètre du piston (mm) | |||

| Débit nominal | Pression de refoulement nominale (Bar) | |||||||

| M³/H | L/ min | |||||||

| 11.7 | 195 | 280 | 330 | 400 | 450 | 45 | ||

| 14.4 | 240 | 220 | 270 | 330 | 360 | 50 | ||

| 17.7 | 295 | 190 | 220 | 270 | 300 | 55 | ||

| 21 | 350 | 160 | 190 | 230 | 250 | 60 | ||

| 24.9 | 415 | 130 | 160 | 190 | 210 | 65 | ||

| 28.8 | 480 | 110 | 130 | 170 | 190 | 70 | ||

| 30 | 500 | 10 | 12 | 16 | 18 | 75 | ||

Cas d'application

Nettoyage automatique du réacteur

Nettoyage à haute pression des exploitations agricoles

Nettoyage automatique des lignes d'assemblage

Nettoyage par déphosphoration métallurgique