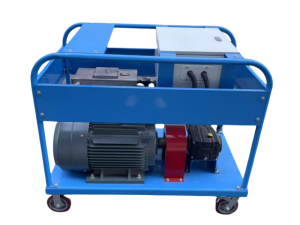

Machine de dragage à tuyau fermé JMT-2-250Bar

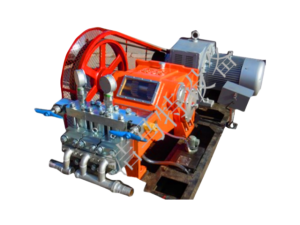

| Modèle | JMT-2 |

| Pression de sortie | 250bar/3600psi |

| Débit d'eau | 250L/min |

| Diamètre du piston | 50 mm |

| Nombre de poussoirs | 3 |

| Vitesse d'entrée | 1480r/min |

| Vitesse de la pompe | 405r/min |

| Course du piston | 95mm |

| Puissance du moteur | 145kw/198HP |

| Taille de l'entrée d'eau | G2-pouce |

Principes de travail

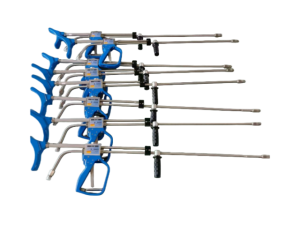

La pompe haute pression génère un jet d'eau à haute pression. Raccorder la buse de débouchage à la pompe via un tuyau haute pression et placer la buse directement à l'intérieur de la canalisation à déboucher.

Lorsque la pompe à haute pression fonctionne, la force de réaction générée par l'eau à haute pression éjectée à l'arrière de la buse pousse rapidement cette dernière vers l'avant. Les jets d'eau haute pression générés par les orifices avant et arrière de la buse nettoient rapidement le tuyau.

Lorsque le ramasseur de tuyaux tire la buse vers l'arrière, le flux d'eau à haute pression chasse la saleté du faisceau de tuyaux.

Applications : Utilisé pour déboucher et dégager les canalisations obstruées dans les parcs municipaux, résidentiels et industriels.

Caractéristiques et avantages du produit

1. Technologie avancée, structure compacte, transmission souple et fiable.

2. Pression stable et fiable, réglage facile.

3. Acier inoxydable, huile de silicone résistante aux chocs et affichage de la pression.

4. La lubrification forcée de la partie motrice réduit les frottements et améliore le pouvoir lubrifiant, ce qui garantit une transmission souple et fiable.

5. Tête de pompe en acier inoxydable forgé, robuste et durable.

6. L'accouplement synchrone assure un fonctionnement stable.

7. Le corps de la pompe haute pression est en fonte ductile ; excellente dissipation de la chaleur, texture dure et résistante à la déformation.

8. L'équipement est équipé d'un filtre qui filtre avec précision les impuretés présentes dans l'eau entrante, ce qui permet de prolonger la durée de vie de la pompe à eau.

9. Disponible avec un moteur électrique ou un moteur diesel.

Applications Industrie

1. Nettoyage multi-applications, y compris le nettoyage des canalisations des propriétés résidentielles.

2. Nettoyage multi-application, y compris le nettoyage et le débouchage des canalisations municipales.

3. Nettoyage multi-applications, y compris le nettoyage des conduites des tunnels de dérivation.

4. Nettoyage multi-applications, y compris le nettoyage des tunnels et des canalisations.

5. Nettoyage de la coque, nettoyage du pont, décontamination et élimination de la végétation marine du fond des navires.

6. Équipement métallurgique et atomisation métallurgique.

7. Usines de fabrication de machines, y compris le nettoyage des cuves, des tuyauteries, de la rouille et du calcaire.

8. Nettoyage des tuyaux de la cimenterie, élimination de la graisse et de la saleté sur les surfaces des équipements.

9. Nettoyage, remise à neuf, etc. de supports hydrauliques miniers.

Spécification détaillée du produit

| Vitesse d'entrée (r/min) | 1480 | Course du piston (mm) | 95 | |||||

| Taux de réduction (i) | 3.65 | Vitesse de la pompe (r/min) | 405 | |||||

| Puissance (kw) | 30 | 37 | 45 | 55 | 75 | 90 | Diamètre du piston (mm) | |

| Débit nominal | Pression de refoulement nominale (Bar) | |||||||

| M³/H | L/ min | |||||||

| 2.4 | 40 | 370 | 460 | 22 | ||||

| 3 | 50 | 300 | 360 | 450 | 24 | |||

| 3.9 | 65 | 230 | 280 | 350 | 500 | 26 | ||

| 4.5 | 75 | 200 | 250 | 300 | 380 | 500 | 28 | |

| 5.1 | 85 | 170 | 220 | 260 | 340 | 450 | 500 | 30 |

| 6.12 | 102 | 150 | 180 | 220 | 280 | 360 | 430 | 32 |

| 8.1 | 135 | 110 | 140 | 170 | 210 | 280 | 330 | 35 |

| 10.2 | 170 | 90 | 110 | 140 | 170 | 240 | 280 | 40 |

| 12.9 | 215 | 70 | 90 | 110 | 130 | 180 | 200 | 45 |

| 15 | 250 | 60 | 70 | 90 | 120 | 160 | 190 | 50 |

Cas d'application

Nettoyage des tuyaux de ciment

Nettoyage des conduites d'égout

Nettoyage de tranchées carrées