Jie Matt Industrial & Compact Pompe à haute pression

- Technologie de base allemande KAMTA

- Fabrication de précision des principaux composants

- Puissance de 30KW à 90KW

- Nombreuses configurations, adaptées à divers scénarios industriels

- Conception écologique et respectueuse de l'environnement

- Supporte une variété de milieux tels que l'eau propre et l'huile fine

Avantages

Une solution à l'épreuve du temps qui évolue avec vous - pour garantir l'efficacité et la durabilité du nettoyage.

Capacité

Diamètre du piston 22 mm-45 mm en option, débit 2,4 m³/h à 10,2 m³/h, pression jusqu'à 500 bars, répondant à toutes les exigences de la scène, de l'alimentation en eau propre/huile fine à la pompe à haute pression au nettoyage à haute résistance.

Système

Fonctionne de manière stable et peu bruyante, supporte les opérations à haute intensité à long terme et prolonge la durée de vie de l'équipement.

Respect de l'environnement

Aucun agent chimique n'est nécessaire, seuls l'électricité et l'eau sont nécessaires pour fonctionner, ce qui réduit considérablement la pollution de l'environnement et les coûts d'exploitation et de maintenance.

Modèles en vogue

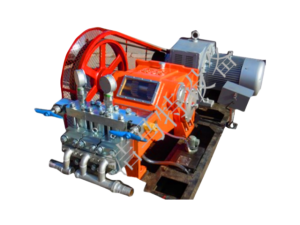

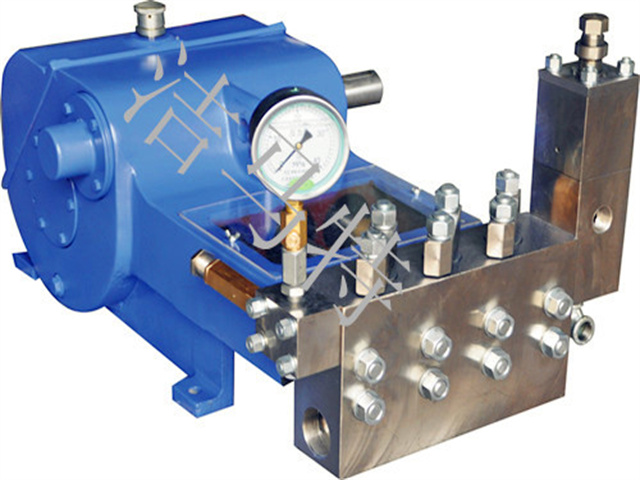

Série Jie Matt -1

Pompe à brouillard d'eau à haute pression

- Haute pression jusqu'à 500Bar

- Débit nominal 2,4-10,2 m³/h

- Couvre rapidement le foyer d'incendie

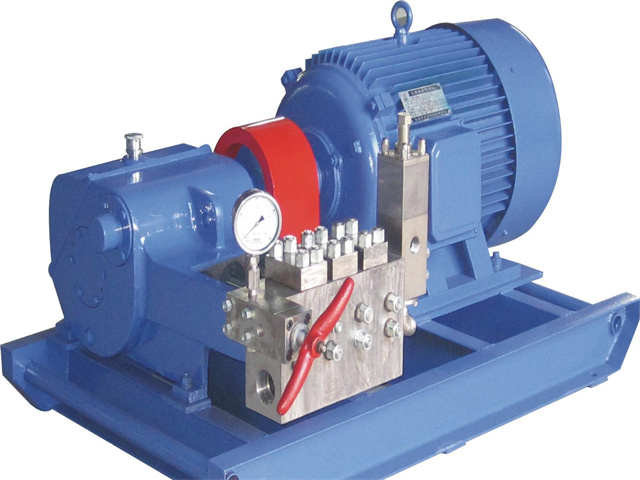

Série Jie Matt -2

Pompe de dessalement de l'eau de mer

- Pression jusqu'à 500 bar

- Puissance de 30KW à 90KW

- Pompage de l'eau de mer, soutien au système d'osmose inverse

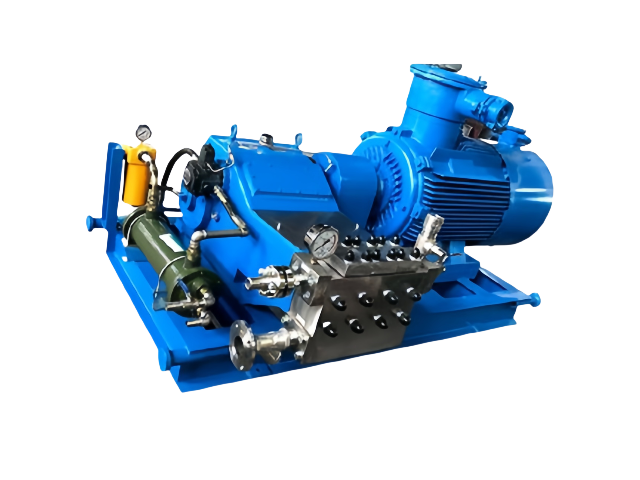

Série Jie Matt -6

Pompe de refroidissement à haute pression

- Vitesse : 1480 min-¹

- Pression : 1000Bar

- Fonctionnement continu et stable dans un environnement à haute température (≤150℃).

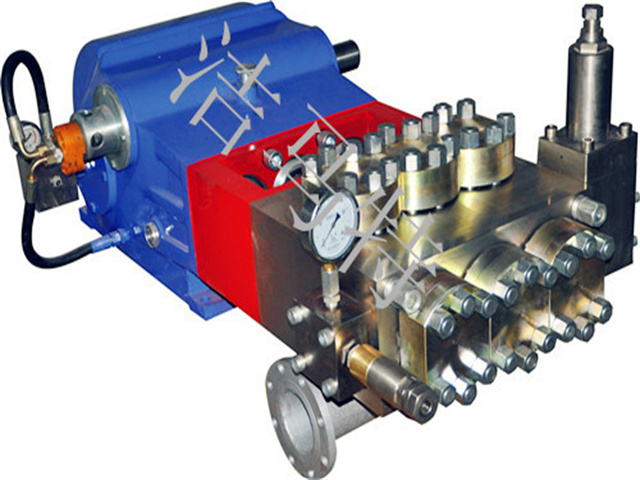

Série Jie Matt -3

Pompe pour la métallurgie des poudres

- Pression jusqu'à 500 bar

- Puissance de 30KW à 90KW

- Le moulage de poudres métalliques fournit une source de pression stable qui garantit la densité et l'homogénéité du produit.

Série Jie Matt -5

Non-tissé filé pompe

- Pression jusqu'à 500 bar

- Puissance de 30KW à 90KW

- Débit nominal : 40-110 L/min

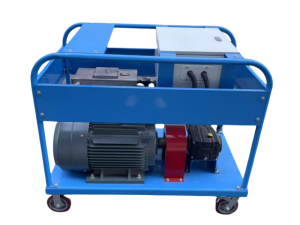

Série Jie Matt -6

Osmose inverse pompe

- Entraînement direct et par courroie

- Machine à eau chaude et machine à eau froide

- Petite taille, grande puissance, facile à déplacer

Série Jie Matt -6

Pompe de déphosphoration de l'eau

- Débit jusqu'à 38,3 m³/h

- 160-250KW haute puissance

- Pression 125-980Bar

- Décapage rapide de la couche d'oxyde sur la surface de l'acier

Série Jie Matt -6

Pompe d'essai de pression de pipeline

- Pression : 1500-3000Bar

- Supporte une variété de milieux tels que l'eau propre et l'huile fine

- Vérifier avec précision l'étanchéité des oléoducs et gazoducs pour prévenir les risques de fuite

Série Jie Matt -6

Pompe d'injection d'eau pour champs pétrolifères

- Puissance 90-300kW

- Les pompes à huile utilisant la technologie de régulation de la vitesse à fréquence variable réduisent la consommation d'énergie de 25%

- Applicable au développement de réservoirs à faible perméabilité

Notre champ d'action

Fondée le 10 septembre 2008, l'entreprise conçoit et fabrique des machines de nettoyage à haute pression. Nos équipements sont utilisés dans les secteurs suivants : pétrole, chimie, sidérurgie, transport maritime, hydroélectricité, sucre, charbon, exploitation minière, construction, construction automobile, assainissement municipal, essais de pression sur les pipelines, etc.

Nos principaux produits : Machine de nettoyage à ultra-haute pression, piston à haute pression, pompe à eau, machine de nettoyage de tuyaux, machine de nettoyage à eau chaude à haute pression, machine de dépolissage à haute pression, pompe d'essai de pression, pompe à coulis à haute pression, machine de découpe au jet d'eau et accessoires, etc.

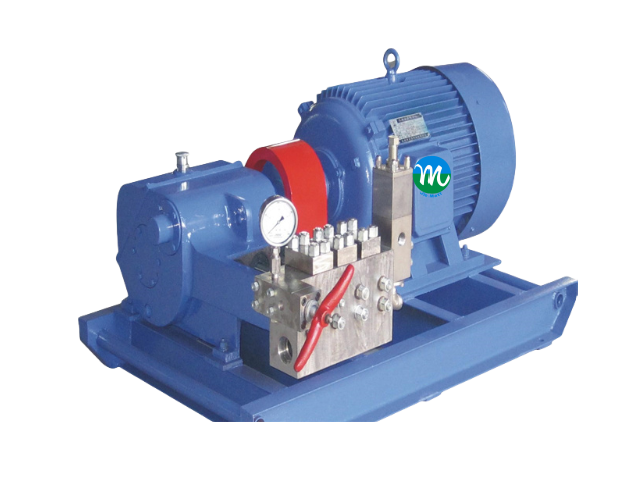

Pourquoi choisir la pompe à haute pression Jie Matt ?

En tant qu'équipement énergétique de base dans le domaine industriel, la pompe à haute pression lancée par Henan Jiematt est devenue l'équipement de protection contre les incendies, de construction navale, d'énergie, de construction et d'autres industries grâce à la technologie allemande Womar, à la conception compacte de la pompe à haute pression, à l'énergie et aux caractéristiques de protection de l'environnement vertes.

La gamme de produits couvre des besoins diversifiés tels que les pompes à haute pression pour les essais de pression sur les pipelines, les pompes à haute pression pour le dérouillage des navires, les pompes à haute pression pour l'entretien des cimenteries, etc., ce qui permet de répondre pleinement aux besoins dans le domaine du nettoyage industriel et du transport des fluides.

Scénarios d'application multisectoriels : répondre précisément aux besoins et améliorer l'efficacité

Pompe haute pression pour le dessalement de l'eau de mer : le pompage de l'eau de mer, la stabilité du fonctionnement du système d'osmose inverse et la promotion du développement durable des ressources en eau douce.

Pompe à haute pression pour le dérouillage des navires : Le flux d'eau à haute pression élimine rapidement la rouille de la coque et les attaches, prolonge la durée de vie du navire et remplace le nettoyage chimique traditionnel.

Essai de pression d'un pipeline à l'aide d'une pompe à haute pression : s'adapte à des milieux tels que l'eau propre et l'huile fine, détecte avec précision l'étanchéité des pipelines et assure le transport du pétrole, du gaz, des produits chimiques, etc.

Nettoyage d'entretien industriel :

Pompe haute pression pour l'entretien de la cimenterieLe système d'alimentation en eau de l'usine de traitement de l'eau est le suivant : il élimine l'agglomération du four et le dépôt de poussière afin d'améliorer l'efficacité du fonctionnement des équipements.

Pompe à haute pression pour le nettoyage d'une usine d'amidon : nettoyer les résidus de la chaîne de production, éviter la contamination biologique et garantir des normes d'hygiène de qualité alimentaire.

Service personnalisé : conception sur demande, ventes directes dans tout le pays

Henan Jiemate propose un service de "vente directe de pompes à haute pression à l'échelle nationale", aidant les clients à personnaliser les combinaisons de paramètres en fonction des conditions de travail réelles. A titre d'exemple :

- Petite scèneModèle à débit de 3 m³/h, pression de 300 bars, adapté à la protection contre les incendies dans les collectivités ou aux tests de pression sur les canalisations légères.

- Demande importante : Débit de 10,2 m³/h, pression de 240 bar, pompe haute performance, spécialement conçue pour la construction navale ou les projets de dessalement de l'eau de mer.

Tous les produits peuvent être livrés rapidement, la ligne d'assistance téléphonique 24 heures sur 24 (180-0385-3609) fournit des services de consultation technique et de devis, aidant ainsi les entreprises à réduire leurs coûts et à accroître leur efficacité.

Pourquoi choisir la solution de nettoyage à haute pression Jie Matt ?

Jiemate se distingue par une série d'avantages conçus pour répondre aux exigences rigoureuses du nettoyage industriel, combinant des composants de première qualité, des services complets et des caractéristiques innovantes.

Des composants de première qualité pour plus de fiabilité

Allemand - Pièces maîtresses: Équipé de pompes à ultra-haute pression et de buses rotatives tri-nation. Ces composants clés garantissent une efficacité de nettoyage élevée et une durabilité à long terme, assurant des performances stables dans les tâches de nettoyage des aciéries.

Adoptant la technologie de la pompe à piston, la plage de pression est réglable de 500 à 3000 bars, ce qui convient à divers polluants tenaces tels que les taches d'huile, la rouille et le béton. L'efficacité est 5 à 8 fois supérieure à celle du travail manuel.

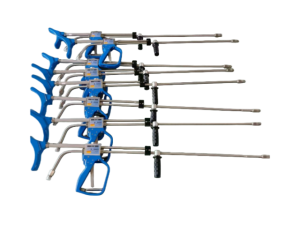

Un service unique pour une expérience sans souci

Des offres complètes: Nous fournissons des pistolets à eau à haute pression, des buses et une assistance technique après-vente. Ce service à guichet unique élimine vos soucis, depuis la fourniture de l'équipement jusqu'à l'entretien ultérieur.

Fonctionnement respectueux de l'environnement

Nettoyage de l'eau pure: Conduit avec de l'eau pure sans pollution chimique, conforme aux normes industrielles vertes. Également, intégré avec des modules IoT pour ajuster la pression et le débit de l'eau en temps réel, optimisant les processus de nettoyage tout en étant éco-conscient.

Conception intelligente pour économiser l'énergie:

- Contrôle de la conversion de fréquence: Ajuste automatiquement la pression et le débit de l'eau en fonction des conditions de travail, réduisant ainsi la consommation d'eau et d'électricité de 30%.

- Système de circulation: Le taux de filtration et de réutilisation des eaux usées est de 80%, conformément aux réglementations en matière de protection de l'environnement.

Ventes directes rentables

Approvisionnement direct de l'usine: En tant que fabricant de pompes de détartrage à haute pression, Henan Jiemate propose des services personnalisés allant de la recherche et du développement au service après-vente. En éliminant les intermédiaires, nous réduisons les prix des équipements de 15% à 20%, fournissant ainsi des solutions rentables.

Des solutions personnalisées pour des besoins spécifiques

Conception sur mesure: Personnaliser la puissance, la pression et les matériaux résistants à la corrosion (tels que les plongeurs en céramique) en fonction des conditions de travail. Nous proposons également une formation à l'utilisation et une assistance à la maintenance. Pour une consultation technique ou le traitement d'une panne, contactez-nous à tout moment.

- Service de personnalisation complète de la scène: En tant que fabricant sur mesure d'équipements de nettoyage à haute pression, Jiemate fournit...

- Extension des fonctions: Buses rotatives, modules d'eau chaude (80℃), modèles antidéflagrants.

- Mise à niveau des matériaux: Corps de pompe en acier inoxydable 316L, buses revêtues de carbure de tungstène, résistant à la corrosion acide et alcaline.

Gestion intelligente de l'IdO

Surveillance en temps réel:Un écran tactile permet de présélectionner 10 modes de nettoyage en un seul clic. Surveillance en temps réel de la pression, de la température et de l'état de l'équipement, avec une précision d'alerte de plus de 95%.

Spécifications

| Débit nominal | Diamètre du piston | Course du piston | Vitesse de la pompe | Pression de refoulement nominale | |||

| m³/h | L/min | mm | mm | min-¹ | Barre | ||

| 2.4 | 40 | 22 | 100 | 332 | 1000 | ||

| 2.7 | 45 | 24 | 100 | 332 | 850 | 1000 | 800 |

| 3.12 | 52 | 26 | 100 | 332 | 750 | 900 | 1000 |

| 3.6 | 60 | 28 | 100 | 332 | 650 | 800 | 9550 |

| 4.2 | 70 | 30 | 100 | 332 | 600 | 700 | 850 |

Les paramètres peuvent être personnalisés en fonction de vos besoins.

Application de la pompe industrielle à haute pression Jie Matt

Les pompes industrielles à haute pression jouent un rôle crucial dans divers secteurs en raison de leur capacité à générer et à contrôler des flux de fluides à haute pression. Voici quelques applications courantes :

Industrie du pétrole et du gaz

- Stimulation de puits

- Fracturation hydraulique (Fracking): Les pompes à haute pression sont utilisées pour injecter un mélange d'eau, de sable et de produits chimiques dans les puits de pétrole et de gaz à des pressions extrêmement élevées (généralement comprises entre 10 000 et 20 000 psi). Ce processus fracture la formation rocheuse, ce qui permet au pétrole ou au gaz piégé de s'écouler plus librement dans le puits de forage en vue de son extraction.

- Nettoyage et entretien des puits: Ils sont utilisés pour nettoyer les débris, le tartre et d'autres obstructions des puits. Des jets d'eau à haute pression peuvent être utilisés pour éliminer les dépôts susceptibles d'entraver l'écoulement des hydrocarbures.

- Transport par pipeline

- Essais de pipelines: Avant la mise en service d'un nouveau pipeline, des pompes à haute pression sont utilisées pour effectuer des essais hydrostatiques. Ces essais consistent à remplir le pipeline d'eau et à le pressuriser à un niveau supérieur à la pression de fonctionnement prévue, afin de vérifier l'absence de fuites et l'intégrité de la structure.

- Assistance au raclage des pipelines: Dans certains cas, des pompes à haute pression peuvent être utilisées pour faciliter le déplacement des racleurs (dispositifs utilisés pour le nettoyage, l'inspection ou l'entretien des pipelines). Le fluide à haute pression peut aider à pousser le racleur dans le pipeline, en particulier dans les systèmes de pipelines longs ou complexes.

Traitement de l'eau et des eaux usées

- Systèmes d'osmose inverse (OI)

- Les pompes à haute pression sont essentielles pour les usines de dessalement par osmose inverse. Elles pressurisent l'eau d'alimentation (généralement de l'eau de mer ou de l'eau saumâtre) pour la faire passer à travers une membrane semi-perméable qui élimine les sels et autres impuretés. La pression requise peut être comprise entre 800 et 1200 psi, en fonction de la salinité de l'eau d'alimentation et de la conception du système d'osmose inverse.

- Déshydratation des boues

- Dans les stations d'épuration, les pompes à haute pression peuvent être utilisées dans des processus tels que l'alimentation des filtres-presses. Elles pompent les boues dans les filtres-presses à haute pression, ce qui permet de séparer les phases liquides et solides des boues, réduisant ainsi le volume des boues à éliminer ou à traiter ultérieurement.

- Lavage à haute pression pour les installations de traitement

- Pour nettoyer les réservoirs, les réacteurs et les canalisations des usines de traitement de l'eau et des eaux usées, des pompes à haute pression sont utilisées pour générer des flux d'eau à haute pression. Ces flux peuvent éliminer efficacement les débris, les biofilms et les dépôts accumulés, assurant ainsi le bon fonctionnement de l'équipement de traitement.

Industries manufacturières et de transformation

- Traitement des métaux

- Détartrage des aciéries: Dans la production d'acier, les pompes à haute pression fournissent de l'eau à des pressions allant jusqu'à 2000 psi ou plus pour éliminer le tartre (couches d'oxyde) de la surface des brames, des billettes ou des bobines d'acier chaud. Cela permet d'améliorer la qualité du produit final en acier et de faciliter les étapes de traitement ultérieures telles que le laminage.

- Moulage sous pression: Les pompes à haute pression sont utilisées pour fournir la pression nécessaire à l'injection de métal en fusion dans les moules lors des processus de moulage sous pression. Le contrôle précis de la pression est essentiel pour obtenir des pièces coulées précises et de haute qualité.

- Industrie alimentaire et des boissons

- Lavage des bouteilles: Dans les usines d'embouteillage, les pompes à haute pression créent des jets d'eau à haute pression pour nettoyer les bouteilles en verre ou en plastique avant de les remplir. Cela permet de s'assurer que les bouteilles sont exemptes de contaminants.

- Nettoyage des équipements de transformation: Les pompes à haute pression sont utilisées pour le nettoyage des équipements de transformation des aliments à grande échelle, tels que les mélangeurs, les réacteurs et les bandes transporteuses. Le fluide à haute pression peut pénétrer dans les fissures et éliminer les résidus alimentaires, les bactéries et autres contaminants, garantissant ainsi la sécurité alimentaire et le respect des normes d'hygiène.

Construction et exploitation minière

- Forage et excavation de tunnels

- Stabilisation des sols: Les pompes à haute pression sont utilisées pour injecter du coulis (un mélange de ciment, d'eau et d'autres additifs) dans le sol autour des tunneliers ou des sites d'excavation. La haute pression permet de répartir uniformément le coulis, de renforcer le sol et d'éviter son effondrement.

- Assistance au forage et au découpage des roches: Dans certaines opérations de forage de roches, des jets d'eau à haute pression peuvent être utilisés en conjonction avec le forage mécanique. L'eau à haute pression aide à briser la roche, à réduire l'usure de l'équipement de forage et à améliorer la vitesse de forage.

- Construction en béton

- Application du béton projeté: Des pompes à haute pression sont utilisées pour projeter du béton projeté (un mélange de ciment, d'agrégats et d'eau) sur des surfaces. Dans le cas des revêtements de tunnels, de la stabilisation des pentes ou des travaux de réparation, l'application à haute pression assure une bonne adhérence et un bon compactage du béton projeté, ce qui permet d'obtenir une couche de béton solide et durable.

- Démolition du béton: Les jets d'eau à haute pression générés par ces pompes peuvent être utilisés pour la démolition du béton. Le flux à haute pression peut briser les structures en béton sans nécessiter de concassage mécanique à grande échelle, ce qui est avantageux dans les situations où la précision et la réduction du bruit et de la poussière sont nécessaires, comme dans la construction urbaine ou la rénovation de bâtiments historiques.

Aérospatiale et automobile

- Nettoyage de composants aérospatiaux

- Dans l'industrie aérospatiale, les pompes à haute pression sont utilisées pour nettoyer les composants des avions, tels que les pièces de moteur, les ailes et les sections de fuselage. Le fluide à haute pression permet d'éliminer les contaminants tels que la graisse, l'huile et les copeaux de métal, garantissant ainsi que les composants répondent à des normes strictes de sécurité et de performance.

- Peinture et revêtement automobile

- Nettoyage des cabines de peinture: Les pompes à haute pression sont utilisées pour nettoyer les cabines de peinture automobile. L'eau à haute pression permet d'éliminer les éclaboussures, les résidus de peinture et autres contaminants des surfaces de la cabine, ce qui permet de maintenir un environnement propre pour la peinture des véhicules.

- Lavage des composants: Pour le nettoyage des composants de moteurs automobiles, des pièces de transmission et d'autres pièces critiques avant l'assemblage ou après l'usinage, les pompes à haute pression constituent un moyen efficace d'éliminer la saleté, les copeaux de métal et les fluides de coupe.

Vous avez besoin d'aide pour déterminer quelle machine convient le mieux à votre entreprise ?

Envoyez-nous un courriel dès aujourd'hui. Nous vous montrerons le fonctionnement de nos équipements et nous vous aiderons à élaborer votre plan. Trouvons ensemble la solution qui permettra à vos activités de rester propres, sûres et efficaces.

Produits Applications

Nettoyage de la rouille

Métallurgie des poudres

Essai de pression des tuyaux

Nettoyage du béton

Nous nous engageons à fabriquer des produits de la meilleure qualité possible aux prix les plus compétitifs. C'est pourquoi nous invitons sincèrement toutes les entreprises intéressées à nous contacter pour de plus amples informations.