JMT-5-1500bar Serie Motor-Hochdruckreiniger

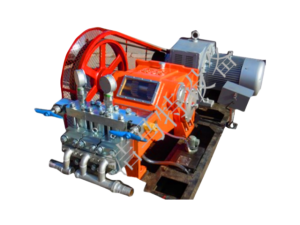

| Modell | JMT-5 |

| Ausgangsdruck | 1500bar/21750psi |

| Wasserdurchflussmenge | 50L/min |

| Plunger-Durchmesser | 24mm |

| Anzahl der Stößel | 3 |

| Eingabe Geschwindigkeit | 1480r/min |

| Drehzahl der Pumpe | 366r/min |

| Stößelhub | 120mm |

| Motorleistung | 160kw |

| Schmierung Methode | Erzwungene Schmierung |

| Methode der Kühlung | Wasserkühlung |

Produktmerkmale und Vorteile

1. Fortschrittliche Technologie, kompakte Struktur und reibungslose und zuverlässige Übertragung.

2. Stabiler und zuverlässiger Druck, einfache Einstellung.

3. Rostfreier Stahl, stoßfestes Silikonöl und Druckanzeige.

4. Die Zwangsschmierung auf der Antriebsseite verringert die Reibung und verbessert die Schmierfähigkeit, was eine reibungslose und zuverlässige Übertragung gewährleistet.

5. Geschmiedeter Pumpenkopf aus Edelstahl, robust und langlebig.

6. Die synchrone Kupplung gewährleistet einen stabilen Betrieb.

7. Hochdruck-Pumpengehäuse aus Sphäroguss; ausgezeichnete Wärmeableitung, harte Textur und resistent gegen Verformung.

8. Drei Filter filtern präzise die Verunreinigungen des einströmenden Wassers und verlängern so die Lebensdauer der Pumpe.

9. Das Zwangswasserkühlsystem auf der Hydraulikseite reduziert die Temperatur des Stößels.

10. Erhältlich mit Elektro- oder Dieselmotorantrieb.

Anwendungen Industrie

1. Vielfältige industrielle Reinigungsanwendungen, einschließlich der Reinigung von Wärmetauscherrohren, Kondensatorrohren, Luftvorwärmern, Kondensatoren, Rohrleitungen, Reaktoren, Filtern, Reboilern, Tanks und Oberflächen von Anlagen.

2. Druckprüfung von Rohrleitungen, Ventilen/Schläuchen, Druckbehältern und Wasserdruck.

3. Reinigung von Rohrleitungen in Zementwerken, Entfettung von Anlagenoberflächen, Entfernung von Kesselstein und Reinigung des Drehrohrofens.

4. Bauindustrie: Auto-/LKW-Reinigung, Reinigung von Mischtrommeln/Tanks, Reinigung von Teer/Zement/Kleber.

5. Lebensmittelverarbeitungsbetriebe: Reinigung von Mischtanks, Entfernung von Fetten/Schlämmen/Rückständen, Reinigung von Verdampfern/Kesseln.

6. Werft: Rostentfernung, Farbentfernung, Reinigung des Schiffsrumpfes, Reinigung des Schiffsdecks, Entfernung von Bewuchs und von Meeresbewuchs auf dem Schiffsboden.

7. Metallurgische Ausrüstung und metallurgische Zerstäubung.

8. Maschinenbaubetriebe: Reinigung von Behältern/Rohren/Behältern, Entrostung/Zunderentfernung.

9. Reinigung und Wiederaufbereitung von Bergbauhydraulik und mehr.

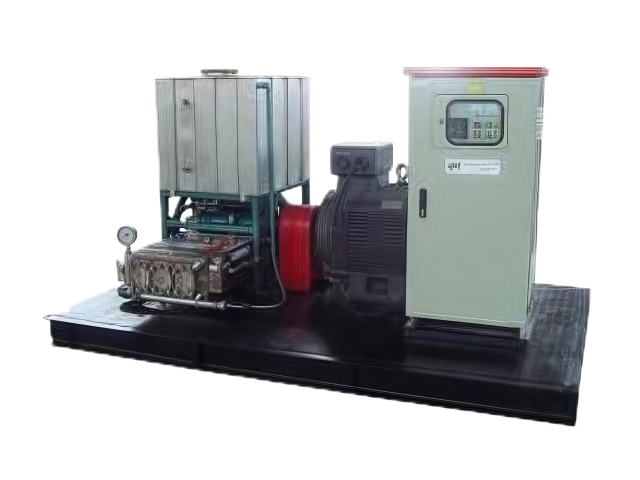

Detaillierte Produktspezifikation

| Eingangsgeschwindigkeit (U/min) | 1480 | Stößelhub (mm) | 120 | ||||

| Verkleinerungsfaktor (i) | 4.04 | Pumpendrehzahl (U/min) | 336 | ||||

| Leistung (kw) | 90 | 110 | 132 | 160 | 200 | Plunger-Durchmesser (mm) | |

| Nenndurchflussmenge | Nenndruck (Bar) | ||||||

| M³/H | L/ min | ||||||

| 2.4 | 40 | 1150 | 1400 | 1500 | 20 | ||

| 3 | 50 | 950 | 1200 | 1400 | 1500 | 22 | |

| 3.6 | 60 | 800 | 1000 | 1150 | 1400 | 24 | |

| 4.2 | 70 | 700 | 850 | 1000 | 1200 | 1500 | 26 |

| 4.8 | 80 | 560 | 700 | 850 | 1000 | 1400 | 28 |

| 5.58 | 93 | 500 | 600 | 700 | 900 | 1200 | 30 |

| 6.06 | 110 | 400 | 500 | 600 | 800 | 1000 | 32 |

Anwendungsfälle

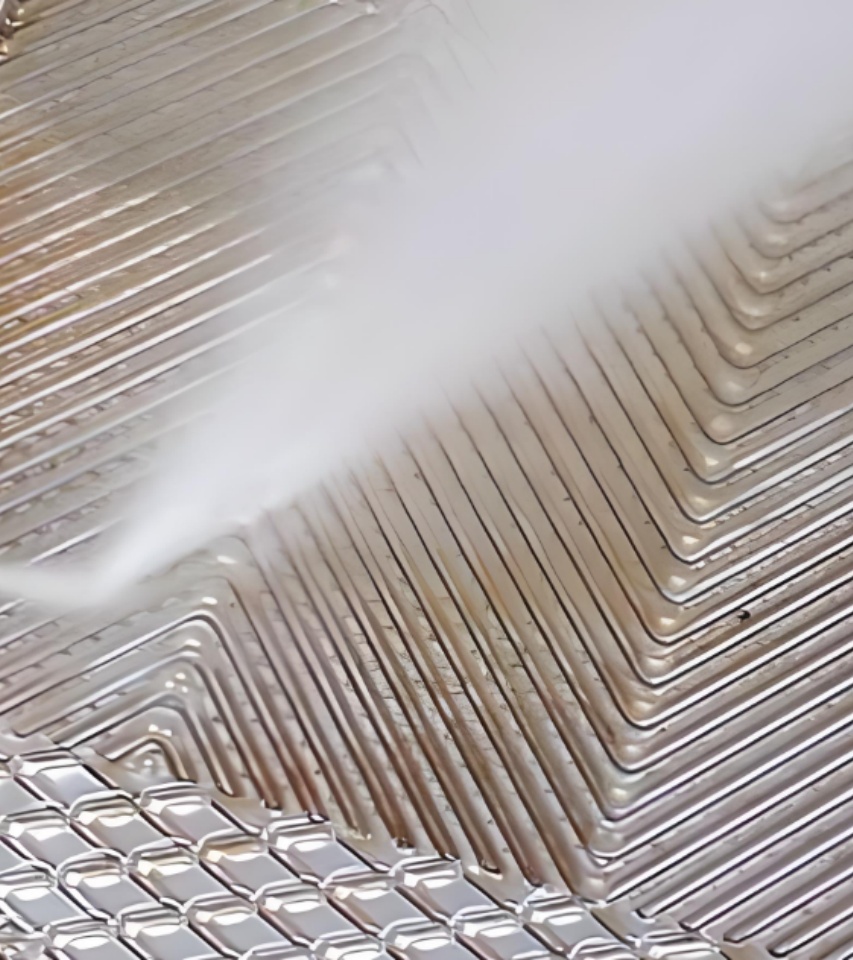

Reinigung von Plattenwärmetauschern

Reinigung des Kondensationswärmetauschers

Hochdruck-Wasserentlackung