Jie Matt Индустриална машина за почистване на бетон под високо налягане

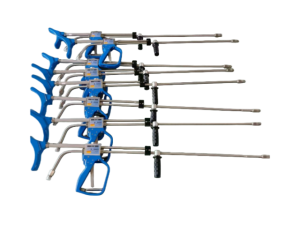

- 2 - 6 пистолета работят едновременно, 3 - 4 пъти по-бързо от пневматичните кирки

- Измийте само повърхността на платформата за леене, разкрийте грапавостта на камъка и намалете загубата на цимент

- Без вибрации по време на промиване, без увреждане на долния слой с грапава повърхност

- Отмиването на примесите спестява време за строителство

- Изравняване на стоманени пръти, фасади, наклони, горни повърхности и др.

- Доставяне на вода под високо налягане в радиус от 150 м без преместване на оборудването, промиване в този диапазон

Ползи

Използва се за бързо почистване на повърхността на бетон след изливане в язовири на водноелектрически централи, за отстраняване и отделяне на големи бетонни маси от стоманени пръти, за почистване на бетонни транспортни ленти, както и за пръскане и задържане на влага.

Основни предимства

Замествайки ръчното къртене с мощни водни струи, той ефективно, чисто и неразрушително обработва бетонни повърхности, като прави строителството по-бързо, по-добро и по-екологично!

Адаптивност към различни сценарии и медии

Той намира приложение в строителни проекти като опазване на водите и хидроенергетиката, строителство на язовири, изграждане на пристанища и мостове и строителство на скоростни пътища.

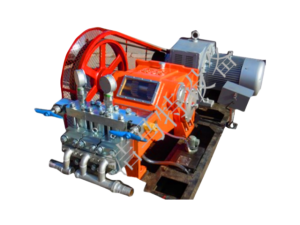

Напор на помпата

Помпа с колянов вал с медна помпена глава, устройство за ограничаване на високото налягане, клапан, механизъм за лесно стартиране, устройство за показване на налягането и високопрецизен филтърен екран.

Горещи модели за продажба

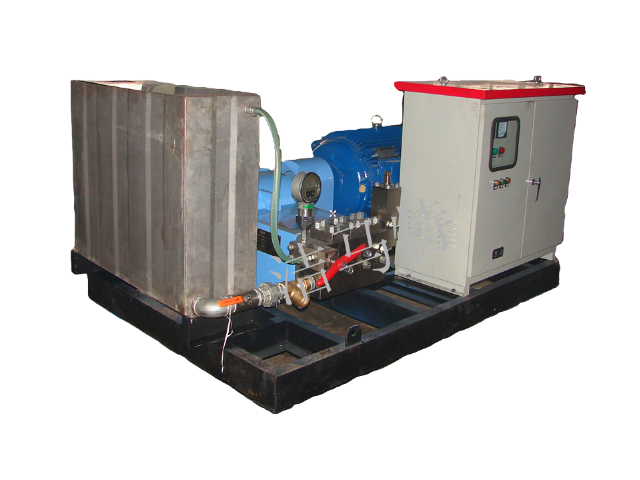

Серия Jie Matt -2

Фиксирана водна струя за изрязване на бетон

- Защитен корпус, идеален за полеви операции

- Поддържа едновременна работа с 2-4 пистолета.

- Доставяне на вода под високо налягане до 150 метра

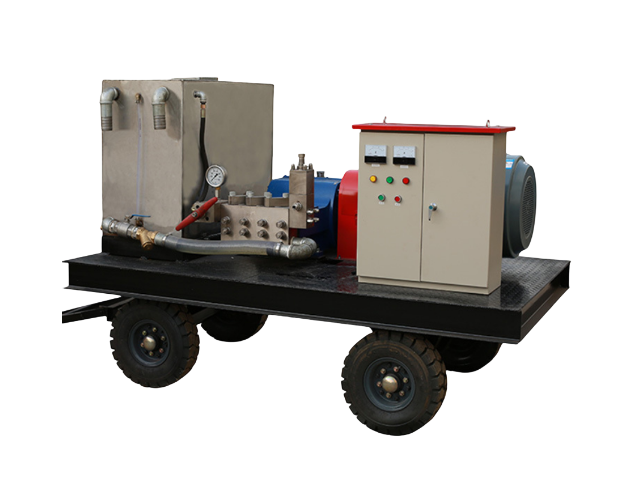

Серия Jie Matt -2

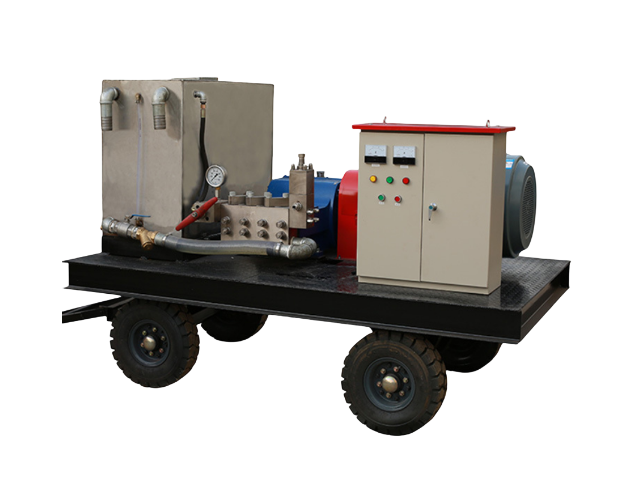

Машина за изкъртване на бетон с многооръдейна водна струя

- Диапазон на налягането 90-500bar

- Побира 2-6 пистолета, работещи едновременно

- Достигане на разстояние до 150 метра с вода под високо налягане

Серия Jie Matt -2

Дизелова водоструйна машина за изрязване на бетон

- Дизелово задвижване за независима работа

- Превъзходна водо- и прахоустойчивост

- Премахва ограниченията, свързани с дължината на кабела

Серия Jie Matt -2

Двуоръдейна водна струя за изкъртване на бетон

- Двата пистолета функционират независимо по едно и също време

- Отделно регулиране на налягането и на водния поток

- Предлага се с прибиращ се прът за пистолет

Серия Jie Matt -2

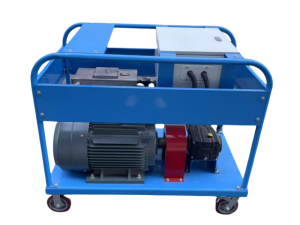

Компактна машина за изкъртване на бетон с водна струя

- Компактен и лек дизайн

- Справя се с труднодостъпното къртене на бетон на малки площи

- По-ниско потребление на енергия

Обхват на дейността ни

Основана на 10 септември 2008 г., ние проектираме и произвеждаме машини за почистване под високо налягане. Нашето оборудване работи в различни отрасли: нефтодобив, химическа промишленост, стоманодобив, корабоплаване, хидроенергетика, захарна промишленост, въгледобив, минно дело, строителство, автомобилостроене, общинска канализация, изпитване на налягането в тръбопроводите и др.

Нашите основни продукти: Машини за почистване под свръхвисоко налягане, бутало за високо налягане, водна помпа, машина за почистване на тръби, машина за почистване с гореща вода под високо налягане, машина за грубо почистване с вода под високо налягане, помпа за изпитване под налягане, помпа за фугиране под високо налягане, машина за рязане с водна струя и аксесоари и др.

Защо да изберем Jie Matt Машина за изстъргване на бетон под високо налягане

В бетонното строителство и свързаните с него дейности широко се използва машина за изкъртване на бетон под високо налягане. Те решават добре проблемите на традиционните методи за обработка. Освен това те отговарят на нуждите на съвременното инженерство за качество, ефективност и опазване на околната среда.

По-добър ефект от лечението, гарантиране на качеството на проекта

Водните струи с високо налягане прецизно отстраняват налепите и свободните слоеве от бетонните повърхности. Те създават равномерно грапав интерфейс. Това значително укрепва връзката между новия и стария бетон.

Освен това намалява структурните рискове като разслояване и напукване. В сравнение с ръчното къртене (което е неравномерно) и механичното къртене (което уврежда основния слой), неговата функция за "неразрушаващо третиране" е по-добра за проекти с високи стандарти.

Това важи с особена сила за проекти със строги изисквания за структурна безопасност, като например язовири и мостове.

По-висока ефективност, съкращаване на времето за изграждане

Една машина работи от 5 до 10 пъти по-бързо от ръчното къртене. При използване на системи с няколко дюзи (например 2 до 6 дюзи едновременно) тя бързо покрива големи бетонни площи. При големи проекти, като изливане на язовири или изграждане на големи подове, това намалява труда. Спира забавянията, причинени от бавното обработване на интерфейса. Освен това ускорява пряко проекта.

Широка употреба, лесна и гъвкава работа

Различните модели отговарят на различни нужди. Малките машини се справят с тесни пространства, като мазета и тръбни шахти. Дизеловите работят без външно захранване, така че са подходящи за работа на терен.

Моделите с няколко дюзи са подходящи за мащабни строителни дейности. Нещо повече, те имат регулируемо налягане, променящи се модели на водния поток и телескопични пръти. Те им позволяват да изпълняват много задачи: от леко къртене до отстраняване на бетон от стомана и почистване на транспортни ленти. Те са много гъвкави.

Полезни за околната среда и спестяващи разходи

Те използват чиста вода. Не произвеждат прах и не вдигат шум. Това отговаря на стандартите за екологично строителство. Затова са чудесни за градски проекти или райони със строги екологични правила, например в близост до жилища.

Първоначалната цена е по-висока от тази на ръчните инструменти. Но в дългосрочен план те спестяват пари. Те намаляват броя на необходимите работници. Намаляват използването на консумативи и разходите за преработка. Освен това с тях се избягва спирането на работата поради замърсяване.

Спецификация

| Модел | Дебит (L/min) | Налягане (bar) | Мощност на двигателя (KW) | Мощност на бензиновия двигател (HP) | Мощност на дизеловия двигател (HP) |

| JMT-2 | 15 | 200 | 5.5 | 13 | 15 |

| JMT-2 | 15 | 250 | 7.5 | 15 | 18 |

| JMT-2 | 23 | 350 | 15 | 24 | 28 |

| JMT-2 | 23 | 500 | 22 | 37 | 36 |

Параметрите могат да бъдат персонализирани според вашите нужди.

Индустриална машина за почистване на бетон под високо налягане

Инженеринг на водните ресурси и хидроенергетиката

- Послойно заливане на язовири на водноелектрически централи: Бетонът за язовирите трябва да се излива на пластове. След изливането на всеки пласт повърхностното омазняване трябва да се обработи бързо, за да се осигури добро свързване между пластовете. Машините за къртене с вода под високо налягане могат да работят ефективно по време на началния етап на втвърдяване след изливането. Водата под високо налягане може да проникне в малки структури като пчелни пити и ямички, за да отстрани замърсяванията. За разлика от механичното къртене, то няма да вибрира в структурата на язовира. Да вземем за пример 30-метров участък от язовирната стена. Моделите с няколко оръдия (например 4-6 оръдия) могат да обработват над 1000 квадратни метра на ден, което е много по-ефективно от ръчното къртене. По този начин се избягва забавяне на последващото изливане поради бавната обработка на междинните слоеве.

- Изграждане на тунелни облицовки: Тунелите имат тесни пространства, в които прахът се разпръсква трудно. Традиционното къртене е не само неефективно, но и произвежда много прах, който вреди на здравето на работниците. Машините за дялане с вода под високо налягане използват чиста вода, така че няма замърсяване с прах. Ръчните или малките модели могат да се движат гъвкаво в тунелите, като прецизно обработват повърхността на облицовъчния бетон. Те са особено подходящи за работа по извитите повърхности на кръгли тунели.

Сложни структури и изисквания за високостандартно свързване

- Изграждане на стълбове и греди на мостове: Компоненти като мостови стълбове и греди трябва да се свързват плътно с опорите и гредите. Качеството на обработката на повърхността влияе пряко върху общата носимоспособност. Машините за водно къртене под високо налягане могат да обработят специално кръглата зона, където горната част на стълба се свързва с тялото на стълба. Налягането на водата може да се регулира в зависимост от якостта на бетона (например 100-150MPa за бетон C30). Това гарантира, че лайната се отстраняват, без да се уврежда стоманеният защитен слой, като се решава проблемът, че при ръчното къртене често се пропускат ъглите.

- Поддържане на пътната настилка: При разширяване на пътища или отстраняване на повреди повърхността на съществуващите бетонни настилки трябва да бъде грапава. Машините за къртене с вода под високо налягане могат бързо да обработват големи площи от пътни настилки, като създават равномерно грапава повърхност. Това осигурява добра основа за нов асфалт или бетон. Те работят с нисък шум (около 70 децибела) и могат да работят през нощта, без да прекъсват движението, което намалява въздействието върху транспортния поток.

Разнообразни сценарии и нужди за опазване на околната среда

- Големи подове и стени на мазета: Строителството на мазета обикновено се извършва в затворени пространства. Механичното къртене произвежда шум и прах, които лесно причиняват замърсяване на околната среда. Машините за къртене с вода под високо налягане са с нисък шум и без прах, като отговарят на изискванията за опазване на околната среда. Малките модели могат да влизат в тесни пространства като асансьорни шахти и шахти за отводняване. Те могат също така да обработят цялостно вътрешните и външните ъгли на стените, като по този начин се избягва евентуално изтичане на вода в бъдеще.

- Производство в заводи за сглобяеми компоненти: Преди да напуснат завода, свързващите повърхности на сглобяемите плочи и греди трябва да се обработят. В производствените линии могат да бъдат интегрирани машини за къртене с вода под високо налягане. С тях се постига автоматично къртене чрез фиксирани релси със стабилна ефективност (всяка сглобяема плоча с размери 3 m × 6 m отнема само 2-3 минути). Грапавостта на повърхността е постоянна, което гарантира, че здравината на свързване отговаря на стандартите при сглобяване на компонентите.

Специални сценарии

- Бетонни конструкции в атомни електроцентрали: Конструкции като сградите на реакторите и защитните обвивки в атомните електроцентрали имат изключително високи изисквания за прецизност и екологичност на обработката на бетонната повърхност. Не се допускат структурни повреди или замърсяване. Тук от съществено значение е функцията "безразрушителна обработка" на машините за къртене с вода под високо налягане. Високопрецизните им филтри предотвратяват попадането на замърсявания във водния поток, като по този начин се избягват драскотини по бетонната повърхност. Освен това оборудването има водоустойчиви и прахоустойчиви характеристики (IP65 или по-високи), като се адаптира към специалната среда на атомните електроцентрали.

- Почистване на бетонни транспортни ленти: Остатъците от бетон често остават дълго време върху транспортните ленти в смесителните станции. Ръчното почистване отнема много време и лесно уврежда повърхността на лентата. Машините за сечене с вода под високо налягане могат да се регулират към воден поток с ниско налягане (30-50MPa) за измиване на лентите. По този начин се отстраняват остатъците, без да се повреждат лентите. Когато са съчетани с подвижни скоби, те могат да постигнат непрекъснато почистване, което подобрява ефективността на оборота на смесителните станции.

Имате нужда от помощ, за да определите коя машина е подходяща за вашия бизнес?

Изпратете ни имейл още днес. Ще ви покажем как работи нашето оборудване в действие и ще ви помогнем с плана. Нека да намерим решението, което ще поддържа дейността ви чиста, безопасна и ефективна.

Продукти Приложения

Стремим се да произвеждаме продукти с най-високо качество на най-конкурентни цени. Затова искрено каним всички заинтересовани компании да се свържат с нас за повече информация.