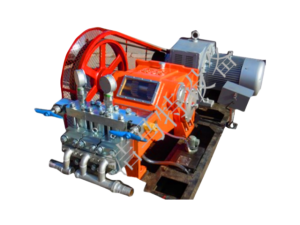

JMT series automatic cleaning system

| Model | JMT-7 |

| Outlet Pressure | 200bar/7250psi |

| Water Flow Rate | 1000L/min |

| Plunger Diameter | 70mm |

| Number of Plungers | 3 |

| Input Speed | 1480r/min |

| Pump Speed | 366r/min |

| Plunger Stroke | 120mm |

| Engine Power | 500KW |

| Lubrication Method | Forced Lubrication |

| Cooling Method | Water Cooling |

Product Features and Advantages

1. Advanced technology, compact structure, and smooth and reliable transmission.

2. Stable and reliable pressure, easy adjustment.

3. Stainless steel, shock-resistant silicone oil, and pressure display.

4. Forced lubrication on the power end reduces friction and improves lubricity, ensuring smooth and reliable transmission.

5. Forged stainless steel pump head, sturdy and durable.

6. Synchronous coupling ensures stable operation.

7. High-pressure pump housing made of ductile iron; excellent heat dissipation, hard texture, and resistant to deformation.

8. The equipment is equipped with a filter to precisely filter impurities in the incoming water, which is beneficial to extending the service life of the water pump

9. Available with either electric motor or diesel engine drive.

Equipment Description

This equipment is a pass-through spray cleaning and drying line designed to meet the manufacturing industry’s growing demands for higher cleanliness standards and increased cleaning output. It integrates mature technologies such as spray cleaning, tunnel drying, and internal circulation drying. Its core features are as follows:

- Adopts stainless steel chain transmission, and is equipped with a low-pressure spray area, high-pressure washing area, air knife water-cutting area, tunnel-type internal circulation drying area, and loading/unloading area, with a high degree of automation.

- Aiming at the characteristics of workpieces with multiple types, complex shapes, and porous/deep-hole structures, a low-speed rotation function is set during the cleaning and drying process to ensure thorough cleaning and drying.

- Suitable for the production scenarios of metal utensils and hardware electrical appliances, it is an ideal automated cleaning equipment for relevant manufacturers.

Purpose and Application Fields

- Purpose: Removes impurities such as cutting fluid, burrs, dirt, oil stains, and metal chips attached to the surface of parts.

- Application Fields: Automobile manufacturing, aluminum part processing, electronic appliances, machinery manufacturing, aerospace satellites, meat processing plants, etc.

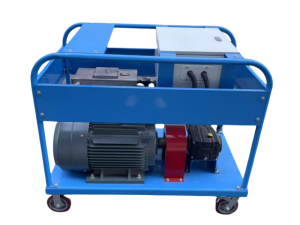

System Composition

- High-pressure cleaning system: High-pressure water pump, variable-frequency motor

- Control system: Variable-frequency electric control box, PLC + touch screen automatic control system

- Conveyor mesh belt chain and transmission system

- Fine filtration system

- Compressed air blowing system

- Drying system

Parameters of High-Pressure Cleaning System

- Pressure range: 50bar – 1500bar

- Flow rate range: 40 – 500L/min

- Customization available according to customer requirements.

Detailed Product Specification

| Input Speed (r/min) | 1480 | Plunger Stroke (mm) | 120 | |||||

| Reduction Ratio (i) | 3.04 | Pump Speed (r/min) | 336 | |||||

| Power (kw) | 110 | 132 | 160 | 200 | Plunger diameter (mm) | |||

| Rated Flow Rate | Rated Discharge Pressure (Bar) | |||||||

| M³/H | L/ min | |||||||

| 11.7 | 195 | 280 | 330 | 400 | 450 | 45 | ||

| 14.4 | 240 | 220 | 270 | 330 | 360 | 50 | ||

| 17.7 | 295 | 190 | 220 | 270 | 300 | 55 | ||

| 21 | 350 | 160 | 190 | 230 | 250 | 60 | ||

| 24.9 | 415 | 130 | 160 | 190 | 210 | 65 | ||

| 28.8 | 480 | 110 | 130 | 170 | 190 | 70 | ||

| 30 | 500 | 10 | 12 | 16 | 18 | 75 | ||

Application Cases

Automatic reactor cleaning

High-pressure cleaning of farms

Automatic assembly line cleaning

Phosphorus removal from hot rolled steel plates