JMT-1RS 250Bar Series Hot Water High Pressure Cleaner

| Model | JMT-1 |

| Outlet Pressure | 250bar/3600psi |

| Water Flow Rate | 15L/min |

| Plunger Diameter | 18mm |

| Number of Plungers | 3 |

| Input Speed | 1480r/min |

| Plunger Stroke | 21mm |

| Engine Power | 7.5KW |

| Lubrication Method | Splash lubrication |

Product Features and Advantages

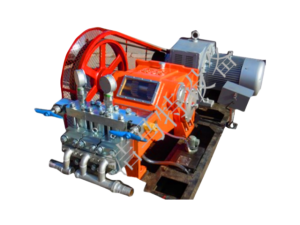

1. The high-pressure pump utilizes imported Italian technology, featuring a pump head made of carefully selected forged materials, a high-pressure all-ceramic plunger, and a 40Cr crankshaft that undergoes precision forging and oxidation treatment.

2. The pressure regulating valve features a stainless steel body and alloy valve core and seat, offering high temperature, high pressure, and corrosion resistance. It is compact, easy to adjust pressure, and highly sensitive.

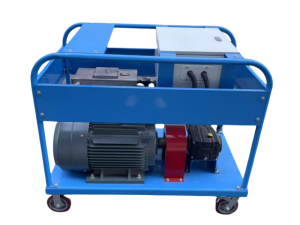

3. The device is compact and lightweight, offering easy operation and portability. It utilizes pure high-pressure water for physical cleaning, eliminating the need for chemical agents and ensuring zero pollution. It is a green, environmentally friendly, high-tech product promoted by the government.

4. Available drive options include electric motor, gasoline engine, diesel engine, air source, and hydraulic motor.

5. Advanced technology ensures a compact structure and smooth and reliable transmission.

6. Stable and reliable pressure is ensured, making adjustment easy.

7. Stainless steel, shock-resistant silicone oil, and pressure display.

8. A forged pump head ensures durability.

9. A coupling provides synchronous connection for stable operation.

10. The high-pressure pump housing is made of ductile iron, offering excellent heat dissipation, a hard texture, and resistance to deformation.

11. The unit is equipped with three filters to precisely filter incoming water impurities, extending the pump’s service life.

Product Performance

1. Industrial-Grade Crankshaft Pump: Equipped with a copper pump head and an oil sight glass for easy oil level monitoring.

2. High-Performance Stepless Pressure Regulating Valve: Delivers strong pressure while ensuring safe and stable operation.

3. 4-Stage Horizontal All-Copper Motor: Boasts powerful horsepower for reliable performance.

4. Industrial-Grade Stainless Steel Heating Furnace: Features a thermal efficiency of over 93%.

5. Industrial-Grade Ceramic Plungers: Capable of continuous operation for extended periods.

6. Safety Protection for Heating Furnace: Equipped with dry-burning prevention and a water cutoff protection switch.

7. Machine Body: Finished with black electrostatic spray painting for an elegant and sleek appearance.

8. Built-In Water Inlet Filtration System: Prevents impurities from entering the system, protecting internal components.

9. High-Strength Casters: Including universal wheels and inflatable wheels for easy movement of the entire machine.

Application Industries

1. Various industrial applications, pumping clean water.

2. Pipeline pressure testing, valve/hose pressure testing, pressure vessel testing, hydraulic testing, etc.

3. Machine tool coolant delivery.

4. Construction industry, car/truck washing, mixing drum/tank cleaning, tar/cement/adhesive cleaning, etc.

5. Food processing plants, mixing tank cleaning, grease/sludge/residue removal, evaporator/boiler cleaning, etc.

6. Shipyards, rust and paint removal, hull cleaning, deck cleaning, fouling removal, and marine growth removal from ship bottoms.

7. Metallurgical equipment, metallurgical atomization.

8. Machinery manufacturing plants, cleaning of vessels/pipes/tanks, rust/scale, etc.

9. Mining hydraulic support cleaning, remanufacturing, etc.

10. Multi-field industrial cleaning applications, including heat exchanger tube cleaning, condenser tube cleaning, air preheater, condenser, pipeline cleaning, reactor cleaning, filter cleaning, reboiler cleaning, tank cleaning equipment surface cleaning, etc.

Detailed Product Specification

| Models | Flow(L/min) | Pressure (Bar) | Power (kw) | Temperature (Celsius) | Heating method |

| JMTRS-1 | 15 | 200 | 5.5kw | 90 | Diesel/Electric |

| JMTRS-1 | 15 | 250 | 7.5kw | 90 | Diesel/Electric |

| JMTRS-1 | 18 | 300 | 11kw | 90 | Diesel/Electric |

| JMTRS-1 | 23 | 350 | 15kw | 90 | Diesel/Electric |

| JMTRS-1 | 23 | 500 | 22kw | 90 | Diesel/Electric |

Application Cases

Exhaust system oil cleaning

Heavy oil pollution cleaning

Industrial equipment oil cleaning

Road cleaning